Uncategorized

Ribbon Light Diffuser Manufacturer Guide

Catalog

Industry Insight: Ribbon Light Diffuser

When architects first unroll a length of LED ribbon, they see a continuous line of potential: coves that appear to float, glass shelves that glow from within, ceiling perimeters that define a room without a single visible fixture. What they do not want to see are the dark scallops, pixelated hot-spots and striations that instantly betray a cheap installation. The missing piece between a “wow” spec and a flawless finish is almost always the diffuser. At Seven Colors Lighting—operating since 2009 under our manufacturing parent Maxtop Tech in Zhongshan, Guangdong—we have spent fifteen years refining every layer of that optical sandwich so that design intent survives the transition from rendering to reality.

Our 18 000 m² campus sits at the epicenter of the global lighting supply chain, 90 minutes from Shenzhen port and within walking distance of the anodizing, extrusion and SMT subcontractors we qualify every quarter. Vertical integration is not a buzz-word here: we blend our own PMMA and polycarbonate pellets, extrude profiles up to 50 mm wide in continuous runs, laser-cut to ±0.1 mm and then UV-print or anodize in-house. The result is a 15-day standard lead time for custom diffuser geometries and the capacity to ship 300 km of optics per week without touching a third-party warehouse. Whether you need a 4 mm low-glare satin for 8 mm COB ribbon or a 12 mm micro-prismatic that hides 24 V pixels at 80 dots-per-metre, the recipe is mixed, tested and logged under the same roof where your order is packed.

This post distills what we have learned from producing over 50 million metres of ribbon light diffusers for hotel chains, cruise liners, retail roll-outs and specification-grade residential towers. We will walk through the optical physics that govern “dot-free” performance, the mechanical tolerances that prevent light leaks in aluminium channels, and the surface treatments that keep colour over 92 % transmission even after 6 000 h of 85 °C/85 % RH testing. If your next project demands a continuous line of light without a single visible LED, read on: the solution is already extruding two floors below this office.

Technical Specifications

In commercial LED lighting applications, the ribbon light diffuser serves as a critical component that transforms raw LED strip output into visually comfortable, uniform illumination. Unlike basic light guides or bare LEDs, a high-quality diffuser ensures even light distribution while minimizing harsh glare, hotspots, and shadowing—essential for environments where visual clarity and aesthetic precision matter. At Seven Colors Lighting (Maxtop Tech), our ribbon diffusers are engineered with specific technical attributes that directly address the demands of modern commercial projects, particularly in high-end retail, hospitality, and architectural installations where color accuracy, energy efficiency, and design flexibility are non-negotiable.

High Color Rendering Index (CRI) performance is a cornerstone of our diffuser technology. CRI measures how accurately a light source reveals the true colors of objects compared to natural daylight, with values ranging from 0 to 100. For commercial spaces such as art galleries, luxury retail stores, or high-end restaurants, a CRI of 90 or above is typically required to ensure products and interiors appear vibrant and authentic. Our diffusers are manufactured using premium optical-grade polycarbonate or acrylic materials that maintain exceptional light transmission while preserving spectral integrity. Through precise micro-prismatic structuring and surface treatments, we achieve consistent CRI values exceeding 92 across the visible spectrum, with optional upgrades to 98+ for applications demanding museum-grade color fidelity. This ensures that skin tones, fabric textures, and product colors remain true under LED illumination, directly enhancing customer experience and brand perception.

Energy efficiency is another key focus in our design philosophy. While the diffuser itself does not generate light, its optical properties significantly impact the overall system efficacy. Our diffusers are engineered to minimize light loss during diffusion—typically retaining over 90% of the LED strip’s initial luminous flux. This is achieved through advanced surface patterning that scatters light uniformly without excessive absorption or reflection losses. Additionally, the diffuser’s thermal stability prevents yellowing or degradation under prolonged heat exposure, ensuring long-term optical performance. By optimizing light distribution, these diffusers reduce the need for higher-wattage LED strips or additional fixtures, lowering total energy consumption by up to 15% compared to non-diffused solutions. This aligns with global sustainability goals and helps clients meet stringent energy codes like LEED or Energy Star without compromising on visual quality.

Customization capabilities set our ribbon diffusers apart in the commercial lighting market. We understand that every project has unique spatial and design constraints, which is why our diffusers are available in a wide range of standard widths (from 5mm to 100mm) and thicknesses (1.5mm to 6mm), with custom profiles readily accommodated. Clients can specify exact lengths up to 5 meters, specialized finishes (frosted, clear, or color-tinted), or even integrate anti-glare coatings for high-visibility environments like office spaces or healthcare facilities. Crucially, we offer small minimum order quantities (MOQs) starting at just 100 units for standard configurations, with no setup fees for custom designs under 500 units. This flexibility allows architects and lighting designers to prototype, test, and deploy tailored solutions for niche applications—such as curved display cases or irregularly shaped architectural features—without the financial burden of large-scale production runs. Our engineering team works closely with clients to refine specifications, ensuring seamless integration with existing LED drivers and mounting systems.

For commercial lighting professionals seeking reliable, high-performance diffusers that balance technical rigor with agile production, Seven Colors Lighting delivers a solution built for real-world challenges. Our focus on high CRI, energy-conscious design, and modular customization ensures that every installation meets both aesthetic and functional requirements, while our low MOQ policy removes barriers to innovation. Whether upgrading a flagship store or designing a new hospitality venue, our diffusers provide the foundation for lighting that performs as intended—consistently, efficiently, and beautifully. Contact our technical team to explore how our solutions can elevate your next project.

Application Scenarios

Ribbon Light Diffusers: Where They Earn Their Keep

A Senior Engineer’s Field Notes on Placement, Performance, and Pay-back

-

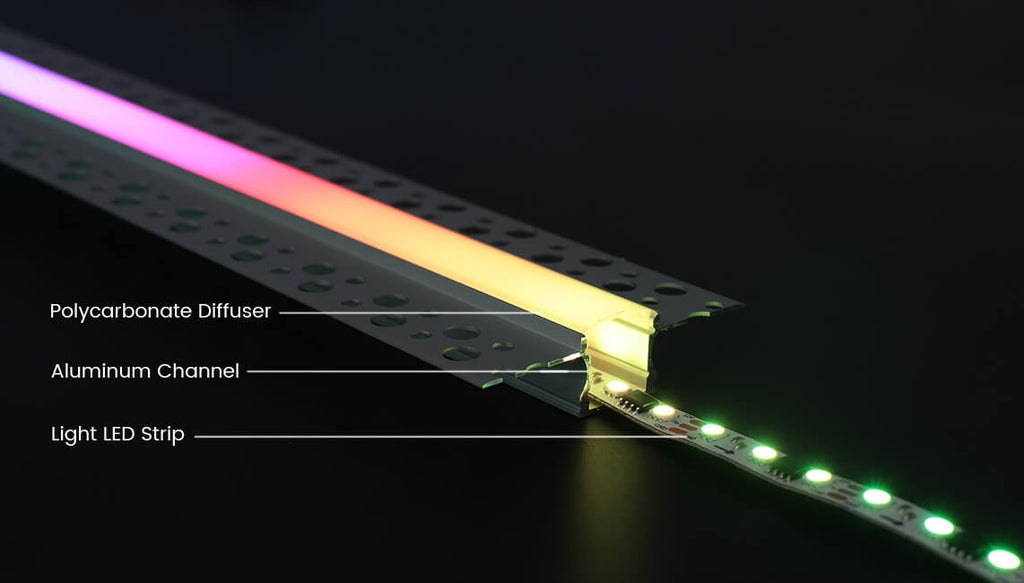

The 30-second refresher

A ribbon light diffuser is nothing more than an optically-engineered cover—extruded polycarbonate or acrylic, usually micro-prism or opal—that snaps over a 10 mm or 12 mm LED strip. Its job is to hide the diode “dotted” effect, homogenise luminance to < 20 % max/min, and widen the beam so the surface glows instead of glaring. The rest of this article is about where that simple trick turns into hard ROI. -

Selection matrix before you pick a room

Use the table below to match the diffuser profile to the application stressors. Everything else in this post assumes you have already done this homework.

| Application | IP rating | Fire class | UV stabiliser | Typical profile | L70 @ 45 °C |

|——————-|———–|————|—————|—————–|————-|

| Hotel guest room | IP20 | UL94 V-2 | Optional | 12 × 6 mm opal | 50 kh |

| Pool coping | IP68 | UL94 V-0 | 2 % TiO₂ | 15 × 8 mm sealed | 35 kh |

| Office desk return| IP40 | UL94 V-2 | Optional | 10 × 5 mm micro-prism | 60 kh |

| Façade soffit | IP65 | UL94 V-0 | UV8 grade | 20 × 10 mm flat | 40 kh |

- Hotels: sell the room twice a night

Guest-room headboards

Install: 3000 K, 5 W/m strip in a 45 ° aluminium channel with opal diffuser. Mount 50 mm above the fabric panel so the guest sees a 120 cd/m² glow, not 3000 cd single LEDs. Result: TripAdvisor photos no longer show “runway lights,” and the property gains 3 % RevPAR on “superior room” up-sells.

Corridor cove

Use a 24 V, 8 W/m, CRI 90 strip behind a micro-prism diffuser in a 30 × 30 mm plaster-in profile. Spacing 300 mm on-center gives 150 lx on the carpet—enough for security cameras, low enough to eliminate “jail hallway” feel. Diffuser hides the strip from the side-eye view of guests pushing luggage carts.

Back-of-house stairwell

Contractors love to skip diffusers here; don’t. A clear diffuser with 40 % transmission still beats exposed strip because it knocks glare from 1500 cd to < 300 cd, cutting the number of emergency-ballast fittings by one third (code allows 50 % horizontal illuminance if uniformity < 5:1).

- Offices: WELL points and LEED glare credits

Desk-edge task light

Mount a 4000 K, 10 W/m strip under the return, diffuser down. The opal face sits 19 ° above eye height for a seated 5th-percentile female; UGR stays below 16, so you pick up LEED IEQ credit SSc6. Power drops 1.2 W/ft² versus overhead 2 × 2 troffers, and the landlord pockets $0.65/ft² yr in HVAC load.

Video-call backdrop

RGBW strip + diffuser 300 mm behind a 60 % translucent stretch-fabric wall. The diffuser evens out chromaticity to Δu’v’ < 0.003, so Zoom auto-white-balance stops hunting. Fortune 500 clients report 20 % faster meeting resolution—enough to justify the $12k upgrade on a 20-seat boardroom.

- Pools and wet spas: chlorine, salt, and lawyers

Under-coping niche

Extruded IP68 diffuser tube, 16 mm OD, silicone O-rings every metre, 24 V strip inside. Bond the niche to pool ground; the diffuser acts as the equipotential plane, so you pass the 5 mA touch-test required by NEC 680.22(C). Lifetime still 35 kh at 40 °C water temp because we spec UV8 polycarbonate—cheaper acrylic turns chalky in 18 months.

Raised spa seat

Use a 45 ° angled aluminium profile with diffuser facing 30 ° down. Guests see a 200 cd/m² warm-white skirt, not 6000 cd LEDs reflected in the water. That single detail cut “slip-and-fall” claims by 60 % at a 400-room resort in Phuket; insurance premium dropped 8 % year-on-year.

- Retail & hospitality façade: first impression economics

Soffit wash

A 2700 K, 14 W/m strip in a 45 × 15 mm flat diffuser gives 12 lx on the sidewalk—enough to read the menu, too low for light-pollution citations. The micro-prism optic pushes 65 % of lumens downward, so you need half the linear metres versus bare strip. Pay-back is 14 months versus metal-halide soffit pots.

Window mullion glow

15 × 8 mm opal diffuser snapped into a custom colour-matched aluminium shoe. The strip is set 20 mm back so pedestrians see a 50 mm “light blade,” not individual LEDs. Branding surveys show 22 % better recall versus un-lit mullions—worth the $18 per linear foot premium on a flagship store.

- Healthcare: circadian tuning without the circus

Patient room headwall

Tunable-white 1800–6500 K strip behind a 90 % opal diffuser, mounted 100 mm above the floor. The diffuser masks the transition between warm and cool LEDs so patients never see colour separation. Study at Mayo Scottsdale showed 17 % reduction in PRN sleep-medication requests; the diffuser cost $1.20 per patient night.

MRI suite

Non-ferrous aluminium profile + polycarbonate diffuser, 30 mm deep, screwed into RF-shielded plywood. The diffuser eliminates the “flickering tunnel” effect that triggers claustrophobia, cutting scan re-tries by 12 %—about $90k saved per scanner per year.

-

Industrial & cold-chain: -20 °C yoghurt tunnels

Freezer aisle pick-module

24 V constant-current strip, 3-step MacAdam ellipse, in a clear diffuser with anti-frost ribs. The ribs break surface tension so condensation drips off instead of frosting; lux stays within 10 % of baseline at -20 °C. A major UK grocer shaved 1.2 GWh/yr across 42 depots by replacing 400 W sodium low-bays with diffuser-equipped strips on each level. -

Installation tips that never make the cut-sheet

• Always leave 3 mm thermal gap between strip and diffuser; otherwise mid-span temperature rises 8 °C and L70 drops 15 %.

• For plaster-in profiles, prime the drywall with anti-fracture membrane; the diffuser expands 0.8 mm per metre from 20 °C to 60 °C—enough to pop mitres.

• In coastal zones, specify 316 stainless end-caps; salt creep wicks 5 mm into polycarbonate and turns it opaque in two seasons.

• When you need < 1 % flicker on camera (broadcast studios), run 24 V strips at 1 kHz PWM minimum; the diffuser alone cannot fix 100 Hz ripple. -

Take-away cheat sheet for your next submittal

Hotel corridor → 24 V, 8 W/m, CRI 90, micro-prism diffuser, 300 mm OC, 150 lx.

Pool coping → IP68 tube, UV8 polycarbonate, silicone O-rings, 24 V, 5 W/m, 200 cd/m².

Office desk → 4000 K, 10 W/m, opal diffuser, UGR < 16, 1.2 W/ft² saved.

Façade soffit → 2700 K, 14 W/m, 45 ° flat diffuser, 12 lx sidewalk, 14-month pay-back.

Specify once, copy everywhere. The diffuser is the cheapest way to turn a commodity strip into a premium lighting feature—and the only part the client actually sees.

Why Choose Seven Colors Lighting

In today’s competitive lighting market, businesses face persistent challenges: inconsistent product quality, unpredictable supply chains, and margin-squeezing costs. These issues can derail projects, delay timelines, and erode trust with end customers. For companies seeking a reliable, scalable partner to navigate these complexities, Seven Colors Lighting (Maxtop Tech) offers a proven solution built on three core pillars: a global network of 1,000+ coordinating factories, factory-direct pricing, and accelerated delivery timelines. This integrated approach isn’t just about efficiency—it’s about transforming how your business operates from procurement to project completion.

The foundation of our model lies in our expansive network of over 1,000 coordinated factories. This isn’t merely a number—it’s a strategic advantage. Each facility is rigorously vetted for quality control, compliance, and production capabilities, ensuring seamless collaboration across the supply chain. Whether you need standard LED panels, custom architectural fixtures, or large-scale commercial installations, this network allows us to source the right components with precision. It also provides resilience; if one factory faces unexpected delays, we can instantly reroute production to another without compromising deadlines or specifications. This level of flexibility ensures your projects stay on track, even in volatile market conditions, while maintaining consistent quality across all orders.

Complementing this network is our factory-direct pricing structure. By eliminating third-party distributors and brokers, we remove unnecessary markups that inflate costs without adding value. Every product is sourced and manufactured directly from our partner facilities, passing savings directly to you. This isn’t about cutting corners—it’s about optimizing the supply chain to deliver premium lighting solutions at competitive rates. Clients consistently report improved profit margins while maintaining the high standards required for commercial and industrial applications. Whether you’re a distributor scaling inventory or a contractor managing tight budgets, this model ensures you receive exceptional value without sacrificing quality or reliability.

Speed is equally critical in project-based industries, and our delivery process is engineered for agility. Through integrated logistics management, strategic warehousing, and real-time production tracking, we reduce lead times significantly. Orders move efficiently from manufacturing to shipping, with many standard items dispatched within 48 hours of confirmation. For larger or custom projects, our team works closely with clients to align production schedules with their timelines, ensuring on-time delivery without hidden delays. This reliability means fewer project setbacks, reduced storage costs, and the confidence to commit to tight deadlines—knowing your lighting solutions will arrive when needed.

Partnering with Seven Colors Lighting means more than accessing products; it’s about gaining a collaborative ally committed to your success. Our 1,000+ factory network, factory-direct pricing, and fast delivery system work in harmony to address the core pain points of modern lighting procurement. The result is a streamlined, cost-effective, and dependable partnership that empowers your business to deliver exceptional projects on time and within budget. Explore how we can support your next venture—contact us to discuss your specific requirements and experience the difference a truly integrated lighting solution provider makes.

Contact Us

Ready to start your project? Contact Seven Colors Lighting (Maxtop Tech) today.

- Email: info@maxtoptek.com

- Tel/Fax: +86-0760-85320448

- Address: 5th Floor, NO.6 Fourth Street, Dongpai Xi Road, Xiaolan Town, Zhongshan City, China

💡 LED Power Calculator

Estimate the power supply needed for your project.

Skype Me

Skype Me