Uncategorized

Drywall Led Channel Manufacturer Guide

Catalog

Industry Insight: Drywall Led Channel

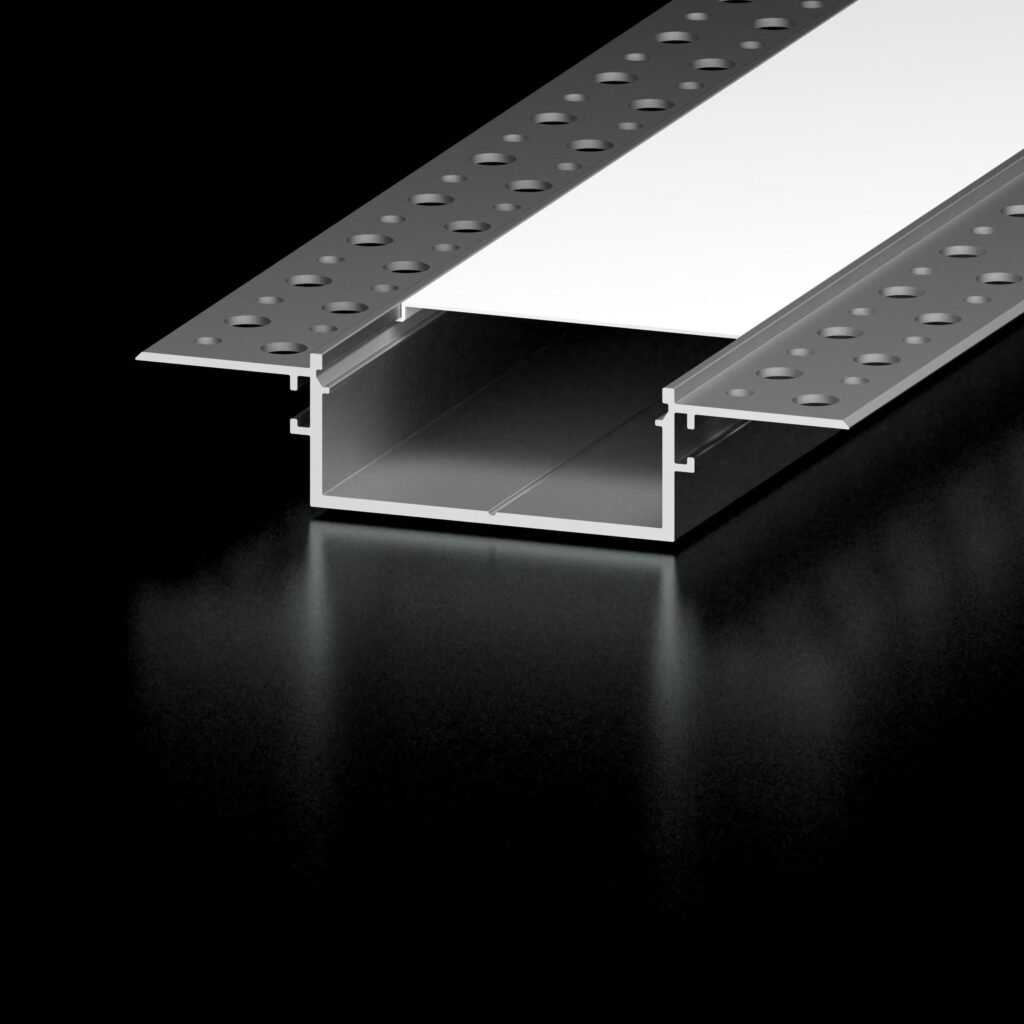

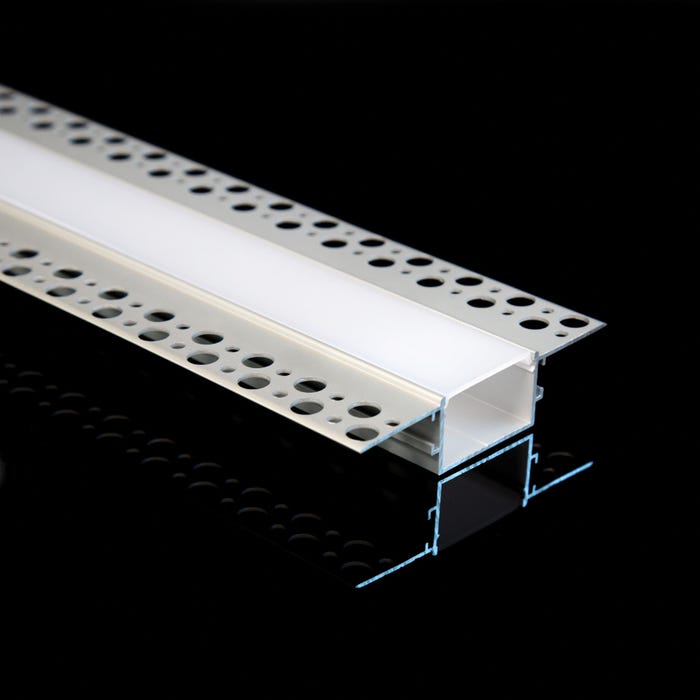

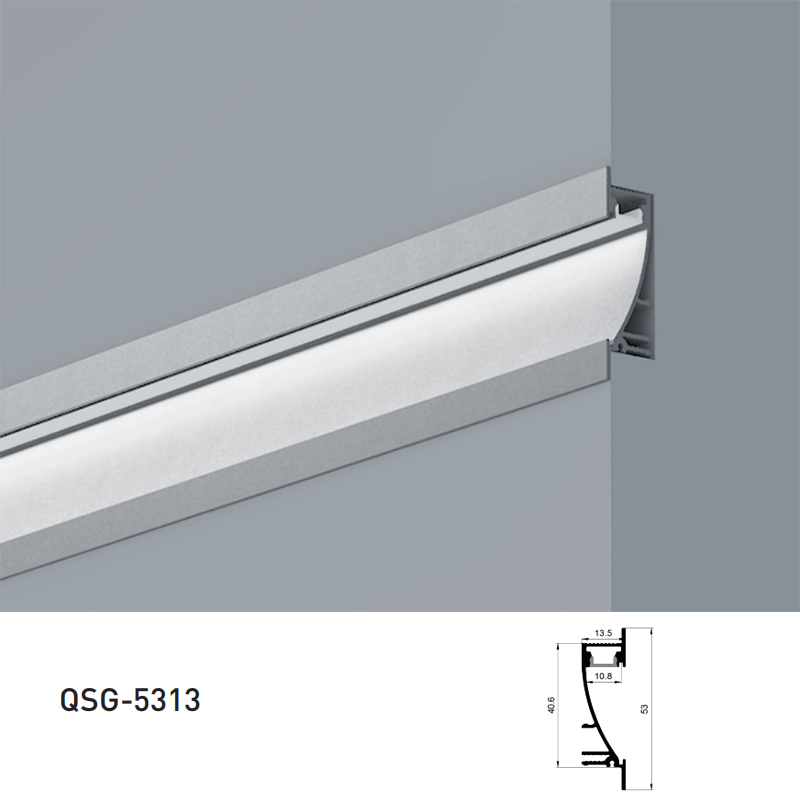

When architects want light to appear as if it is pouring straight out of a wall, they usually specify a drywall LED channel. Also called an LED plaster-in profile, this aluminum extrusion is designed to be mudded directly into gypsum board, so the finished surface is flush with the surrounding plane. Once painted, only a hair-line aperture reveals the light source, eliminating visible fixtures and turning the wall itself into a luminous panel. The concept is simple, yet the details—thermal management, drywall bonding, flange width, paint cracking, and consistent color over long runs—are what separate a premium system from a weekend disappointment.

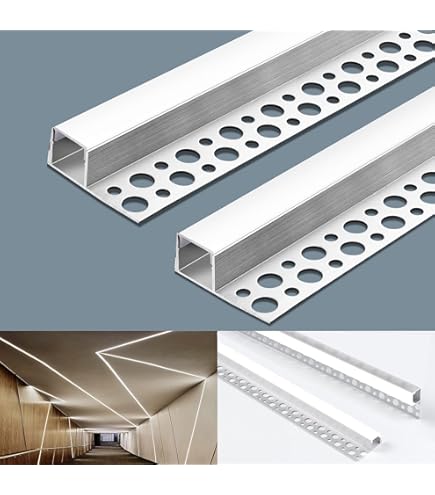

Seven Colors Lighting, operating under the manufacturing name Maxtop Tech, has been refining those details since 2009 from its 30,000 m² headquarters in Zhongshan, Guangdong. Located at the epicenter of the global lighting supply chain, the factory houses 18 aluminum extrusion lines, in-house CNC and anodizing workshops, and a 500-seat assembly floor that together produce more than 1.2 million meters of LED channel every month. Every profile is extruded from 6063-T5 alloy with a minimum 1.2 mm wall thickness to guarantee flatness once embedded, and each lot is salt-spray tested to 48 hours before release. With tooling engineers on site, custom flange widths, depths, and clip geometries can move from CAD to production in under two weeks, giving specifiers the freedom to match exact drywall thicknesses or acoustic panel depths without compromising the clean sightline that defines modern architectural lighting.

Technical Specifications

Drywall LED channels represent a critical component in modern architectural lighting systems, designed to seamlessly integrate LED strips into recessed installations while delivering superior performance and longevity. As a Senior Lighting Engineer at Seven Colors Lighting, I often emphasize how the technical design of these profiles directly impacts the efficiency, safety, and visual quality of lighting solutions. Understanding the interplay between heat dissipation, surface treatments, and diffuser materials is essential for engineers and designers aiming to achieve consistent, high-performance results in commercial and residential projects.

The extruded aluminum profile forms the backbone of effective thermal management. Aluminum’s inherent thermal conductivity allows it to act as a passive heatsink, efficiently drawing heat away from the LED strip and dispersing it across the channel’s surface area. This prevents localized overheating, which can cause premature LED failure, color shifting, or reduced luminous output. Our profiles are engineered with optimized internal geometry and wall thickness to maximize heat transfer, ensuring stable operation even in confined spaces. For instance, in high-density installations where multiple channels are installed in close proximity, this thermal efficiency becomes critical for maintaining consistent light output over thousands of operating hours.

Anodized finishes further enhance the durability and aesthetic versatility of these channels. The anodization process creates a hard, oxide layer on the aluminum surface through electrochemical treatment, significantly improving resistance to corrosion, scratches, and environmental wear. This is particularly valuable in installations exposed to humidity, temperature fluctuations, or frequent cleaning, such as in hospitality or healthcare environments. Beyond functionality, anodized finishes offer a range of color options—from matte white and black to brushed metallics—allowing seamless integration with diverse interior designs without compromising structural integrity. Unlike painted alternatives, anodized surfaces remain uniform over time, eliminating concerns about chipping or fading that could disrupt visual consistency in premium applications.

The polycarbonate (PC) diffuser plays an equally vital role in achieving uniform illumination. This high-transmission material evenly scatters light from the LED strip, eliminating hotspots and glare while maintaining brightness levels. With light transmission rates exceeding 90%, PC diffusers ensure minimal lumen loss, making them ideal for applications where precise light distribution is required, such as retail displays or office environments. Additionally, polycarbonate’s inherent UV resistance prevents yellowing under prolonged exposure, and its impact strength provides protection against accidental damage during installation or maintenance. This combination of optical clarity and physical resilience ensures the diffuser maintains its performance and appearance throughout the system’s lifespan.

At Seven Colors Lighting, we recognize that project requirements vary widely, which is why we prioritize flexibility in manufacturing. Our drywall LED channels support small minimum order quantities starting from just 50 meters, enabling designers to test configurations or complete smaller-scale projects without overcommitting to inventory. Beyond standard offerings, our customization capabilities extend to precise length adjustments, specialized mounting options like concealed screws or adhesive strips, and tailored diffuser finishes—including frosted or clear variants. This adaptability ensures our solutions align with the unique constraints and creative visions of each client, whether for a single boutique installation or a large-scale commercial build.

By integrating these technical elements—robust thermal management, durable anodized finishes, and high-performance PC diffusers—our drywall LED channels deliver reliability, efficiency, and design freedom. For professionals seeking a solution that balances engineering precision with practical flexibility, these profiles provide the foundation for lighting systems that perform consistently and aesthetically across diverse applications. We invite you to explore how our expertise can support your next project with tailored specifications and responsive service.

Application Scenarios

Drywall LED Channel: Where the Detail Becomes the Design Language

In hospitality, commercial and wellness projects the junction between light and architecture is no longer a trim piece—it is the architecture. A drywall LED channel (sometimes called a plaster-in or flush-mount profile) lets the lamp vanish and leaves only the visual effect: a razor-sharp line, a floating ceiling, a cove that breathes color temperature. Below is a field-tested map of where the detail pays off, what to watch for, and how to sell the upgrade to the next owner or operator.

-

Hotels: from arrival to pillow

Lobby reception desk – Recess a 45° angled channel in the stone or timber fascia. The grazing light removes the need for downlights that spill on guests’ faces. Use 5 W/m 3000 K CRI 90+ tape; the channel acts as a heat sink so you can run 24 h without color shift.

Corridor bulkhead – A 10 mm wide drywall channel set 200 mm above the finished floor creates a “floating base” that guides luggage without ceiling glare. Specify a 45° lens so the beam lands on the carpet, not the wall art.

Guest-room headboard – Run a 6 mm plaster-in channel the full width of the wall. Fit it with 2400 K at 1 % for night-mode navigation; guests never touch a bedside lamp switch.

Bathroom mirror – Use a double-row channel (IP44) recessed into the gypsum above the mirror. The front row is 4000 K for shaving; the rear row is RGBW for the “spa scene” triggered by the room-management system. -

Workplaces: light that leases the space

Executive boardroom – Install a 15 × 15 mm square channel around the dropped ceiling cloud. Tunable white (2700–6500 K) follows the circadian schedule programmed by the BMS. Because the channel is plastered flush, the ceiling reads as one uninterrupted plane—important when the space is marketed on Zoom calls.

Open-office spine wall – A vertical 1.5 m channel every 1.2 m replaces the 70 W wall-washer. The micro-prismatic diffuser eliminates pixelation, so employees see a gradient, not dots. Power is 9 W/m; lifetime jumps from 30 000 h to 60 000 h because the aluminum extrusion keeps junction temperature <45 °C.

Reception logo wall – Back-bend a flexible channel to match the company’s curved logo. The drywall crew scores the sheetrock, the electrician pre-wires 24 V, and the painter finishes one coat—no visible fasteners. Result: the sign appears to emit light, not reflect it. -

Wellness & wet zones: IP ratings without visible seals

Indoor pool ceiling – Specify a channel with closed-end caps and silicone-filled ends (IP67). Recess it into the 12 mm moisture-resistant gypsum at the junction between ceiling and bulkhead. Use 1800 K amber to reduce glare off water; the channel’s frosted lens hides individual LEDs so swimmers see a continuous glow.

Spa niche – A 45° plaster-in channel under each teak bench provides 50 lx at floor level, meeting IEC 60598-2-25 for wet locations while staying below 30 °C touch temperature.

Changing-room mirror – Install a 10 mm deep channel around the perimeter of the mirror cut-out. IP44 rating is achieved by a co-extruded gasket that compresses when the mirror is siliconed in place—no visible frame, no rust stains. -

Retail & hospitality F&B

Wine-bar bottle wall – Vertical channels every 400 mm create 30° grazing light that avoids label fade (CRI 95, no UV). The drywall is dado-cut; the channel flange is skim-coated so bottles appear to float.

High-end boutique fitting room – A 3000 K channel ring recessed into the ceiling perimeter eliminates facial shadows. Add a 1 % dim curve; when the shopper steps in, the light fades up over 1.5 s—luxury in the milliseconds.

Restaurant banquette – A 6 mm micro-channel under the lip of the seat lights the floor for staff clean-down while keeping luminance <300 cd/m² at eye height, complying with IES RP-11. -

Public & transit

Airport check-in island – A 40 m continuous run of drywall channel is cast into the corian counter. Expansion joints every 6 m use a flying-splice connector; the diffuser is laser-welded to avoid dirt ingress. Maintenance is from the rear; the counter face never opens.

Museum reveal base – A 10 mm channel set 100 mm above the floor delivers 50 lx on the wall without UV. The plaster-in flange is fire-rated to ASTM E119 2 h, so the channel doubles as a smoke seal.

Installation notes that win the next job

Stud depth – Standard 13 mm flange needs 16 mm total gypsum thickness. In 92 mm metal stud walls, switch to 10 mm flange and add 6 mm backer board to maintain fire rating.

Thermal path – 3 W/m of LED heat needs 4 cm² of aluminum per metre. If the channel is fully surrounded by insulation, derate to 1.5 W/m or add a heat spreader strip.

Joint tolerance – Drywall finishers can keep within ±1 mm over 3 m. Specify a channel with a 2 mm reveal edge; the painter masks it with 6 mm tape, leaving a crisp shadow line.

Driver distance – 24 V tape has 5 % voltage drop at 3 m from feed. For corridors longer than 6 m, loop the feed to both ends or use 48 V constant-current tape inside the same channel profile.

Future retrofits – Choose a channel whose diffuser snaps out from the front. Facilities teams can upgrade from 80 CRI to 97 CRI or from 3000 K to tunable white without touching the plaster.

Selling the line item

Owners respond to two numbers: energy delta and Instagram-ability. A 100 m corridor retrofitted from 50 W downlights to 9 W/m channel cuts 2.8 kW and 14 000 kWh/yr. At 0.12 $/kWh that is US $1 680 saved—enough to justify the drywall patch. Meanwhile the design photographer captures a ceiling with no visible light source, a shot that ends up in the next RFP. In competitive bidding, the channel is no longer a line item; it is the signature.

Why Choose Seven Colors Lighting

In today’s competitive lighting market, procurement decisions directly impact project timelines, budgets, and end-product quality. For businesses relying on consistent, high-performance lighting solutions, the choice of partner isn’t just about cost—it’s about reliability, scalability, and operational efficiency. At Seven Colors Lighting, we’ve built a foundation designed to address these exact challenges through a uniquely integrated approach to manufacturing and supply chain management.

Our global network of over 1,000 coordinating factories forms the backbone of this strategy. Each facility operates under unified quality control protocols, ensuring consistency across all products regardless of location or scale. This network isn’t merely about volume—it’s about resilience. When your project demands rapid scaling or customization, our coordinated system adjusts seamlessly without compromising on precision. Whether you’re managing a single high-end commercial installation or a multi-site rollout across continents, this structure eliminates single-source vulnerabilities and guarantees uniform performance.

The benefits of this model extend directly to your bottom line. By operating a factory-direct model, we remove intermediaries from the supply chain, passing savings straight to you. This transparency means no hidden fees, no distributor markups, and pricing that aligns with the true cost of production. For businesses managing tight budgets or complex procurement workflows, this translates to predictable costs and greater flexibility in resource allocation. Whether you’re sourcing standard fixtures or specialized custom designs, you receive competitive pricing without sacrificing material integrity or craftsmanship.

Speed is equally critical in project execution, and our logistics infrastructure is engineered to minimize delays. Through real-time coordination between factories, warehousing hubs, and shipping partners, we’ve optimized the path from order to delivery. Typical lead times are reduced by up to 30% compared to industry averages, thanks to strategic production scheduling and regional distribution centers. This efficiency ensures your projects stay on schedule, reducing costly downtime and allowing your team to focus on execution rather than chasing shipments.

Partnering with Seven Colors Lighting means more than acquiring products—it’s a strategic alliance built on operational excellence. Our integrated network, transparent pricing, and accelerated delivery timelines work in unison to support your business goals, whether you’re navigating tight deadlines, scaling operations, or seeking long-term supply chain stability. When reliability and efficiency are non-negotiable, we provide the foundation to deliver results, consistently and without compromise.

Contact Us

Ready to start your project? Contact Seven Colors Lighting (Maxtop Tech) today.

- Email: info@maxtoptek.com

- Tel/Fax: +86-0760-85320448

- Address: 5th Floor, NO.6 Fourth Street, Dongpai Xi Road, Xiaolan Town, Zhongshan City, China

💡 LED Power Calculator

Estimate the power supply needed for your project.

Skype Me

Skype Me