Uncategorized

Led Strip Track Manufacturer Guide

Catalog

Industry Insight: Led Strip Track

When an architect wants a line of light that runs 30 m without shadows, or a retailer needs a color-tunable cove that can be re-lamped in minutes, the conversation always drifts to the same component: the LED strip track. Often treated as an afterthought, this slim aluminum extrusion is actually the bridge between a flexible light engine and a precision lighting system. It governs thermal performance, defines the beam angle, locks out dust and moisture, and—most importantly—determines whether the installation will still look factory-fresh five years from now.

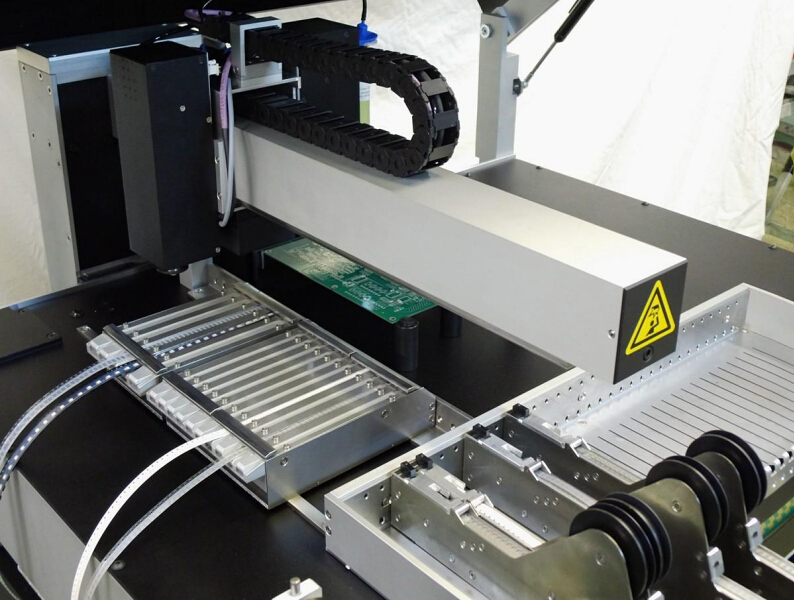

Seven Colors Lighting, operating under the manufacturing name Maxtop Tech, has been refining that bridge since 2009 from a 22 000 m² campus in Zhongshan, Guangdong—the city that produces more luminaires per square kilometer than anywhere else on earth. Unlike trading houses that outsource extrusion, machining, anodizing and final assembly, we keep the entire workflow under one roof: six 1 800-ton aluminum presses feeding a 120 m anodizing line, 42 CNC centers that hold ±0.05 mm tolerance on clip slots and end-cap grooves, and an in-house spectroradiometer that verifies CCT drift < 50 K after 6 000 h at 55 °C. The result is a family of LED strip tracks that ship in 24-hour lead times, carry certifications for UL, CE, RoHS, and marine-grade salt-spray, and can be customized from 8 mm to 120 mm width without a new tooling charge.

For specifiers, that vertical integration translates into three tangible advantages. First, thermal consistency: every meter of extrusion is extruded from 6063-T5 alloy with a guaranteed 205 W/m·K conductivity and a minimum 1.2 mm wall, so a 14.4 W strip runs 12 °C cooler than the same emitter mounted on a 0.8 mm generic profile. Second, optical repeatability: our micro-baffle and opal diffuser plastics are injection-molded in-house from UV-stabilized PMMA, ensuring that the 45° cutoff angle on batch 1 matches batch 1001. Third, logistic agility: because we stock 18 000 km of raw aluminum and 320 tons of polycarbonate on site, we can anodize to any RAL or matte-silver finish and laser-etch a company logo within three days—an essential service when a hotel chain decides at the last minute that every corridor cove must match its brushed-brass door hardware.

In the posts that follow, we will break down the engineering variables—heat-sink geometry, IP rating methodology, clip retention force, and color-over-angle metrics—that turn a simple aluminum channel into a specification-grade LED strip track. Whether you are a lighting designer calculating luminaire lifetime in a 24/7 airport, or an OEM developing a seamless run for a luxury yacht, the starting point is the same: a profile whose thermal, mechanical and optical properties have been proven in our Zhongshan lab before they ever reach your project site.

Technical Specifications

The evolution of magnetic track lighting systems has redefined flexible illumination solutions for commercial and retail environments, and at Seven Colors Lighting, our DC48V LED strip track system represents a significant advancement in safety, efficiency, and adaptability. Designed with modern installation workflows in mind, this system addresses critical pain points for lighting designers, contractors, and facility managers while maintaining rigorous technical standards.

Central to our system’s safety profile is the 48-volt DC power supply. Operating below the 50V safety threshold defined by international electrical standards, this low-voltage architecture minimizes the risk of electric shock during installation and maintenance. Unlike higher-voltage AC systems, DC48V eliminates the need for specialized conduit or complex grounding procedures, simplifying compliance with NEC and IEC regulations. The reduced voltage also allows for thinner, more flexible wiring, cutting material costs and enabling cleaner installations in tight spaces. Crucially, the system maintains consistent power delivery over longer track runs without significant voltage drop, ensuring uniform light output even in expansive retail or gallery settings.

Installation efficiency is another cornerstone of our design philosophy. The magnetic coupling mechanism eliminates the need for tools or additional hardware when positioning fixtures. Simply align the fixture’s magnetic base with the track and slide it into place—no screws, clamps, or electrical connectors required. This not only accelerates deployment but also reduces labor costs by up to 40% compared to traditional track systems. The track itself features a streamlined profile with integrated power rails, allowing for quick connection to the power supply unit. For retrofit projects, the system’s compatibility with standard junction boxes and existing low-voltage infrastructure ensures seamless integration without structural modifications.

Magnet strength is rigorously engineered to prevent accidental dislodgement under real-world conditions. Each fixture’s magnetic base utilizes high-grade neodymium magnets rated for a pull force of 3 to 5 kilograms per contact point, validated through vibration and dynamic load testing. This ensures secure attachment even in high-traffic areas like museums or high-end retail stores where environmental factors such as foot traffic or HVAC airflow could compromise less robust systems. The magnetic interface also allows for effortless repositioning of fixtures during design adjustments or seasonal updates, supporting agile spatial planning without re-wiring.

Recognizing the diverse needs of project stakeholders, we offer flexible ordering options with a small minimum order quantity (MOQ) of just 10 units. This accessibility empowers smaller-scale projects—such as boutique hotels or specialty retail spaces—to leverage our technology without financial commitment barriers. Customization extends beyond basic configurations: we provide tailored track lengths (up to 6 meters per segment), adjustable color temperatures (2700K to 6500K), and specialized finishes including matte black, brushed aluminum, and custom RAL colors. For clients requiring advanced functionality, we integrate dimming protocols (0-10V, DALI) and smart controls directly into the track system.

At Seven Colors Lighting, our DC48V magnetic track system balances technical precision with practical usability. By prioritizing safety through low-voltage design, streamlining installation processes, and delivering robust magnetic performance, we enable partners to deliver exceptional lighting solutions that adapt to evolving project demands. Whether for new construction or high-end renovations, our approach ensures reliability, cost efficiency, and design freedom from concept to completion. Contact us today to explore how our customizable track system can elevate your next project.

Application Scenarios

LED Strip Track: Where the Channel Meets the Ceiling, and Why That Matters

Seven Colors Lighting | Maxtop Tech – Senior Lighting Engineering Team

Spec-grade LED strip has become the default “paintbrush” for modern architectural lighting, but the brush is only half the story. The canvas—the LED strip track (aluminum extrusion, LED channel, profile, call it what you like)—determines beam control, heat dissipation, IP rating, tamper resistance, and ultimately whether the client signs off or calls you back in six months. Below is a field-tested map of where the track goes, what variant earns its keep, and the small print that keeps liability lawyers asleep at night.

- Hotels: From Porte-Cochère to Pillow Mint

Guest-room coves

Use a 12 mm deep, frosted-lens surface-mount track recessed into 13 mm plasterboard. The deeper the channel, the wider the “bat-wing” optic you can snap in, eliminating the dreaded dot-spot on the ceiling that guests photograph at 1 a.m. and post on TripAdvisor. Specify 3-step MacAdam LED and a 90 CRI minimum; the track acts as a heat-sink so you can drive at 14 W/m instead of 10 W/m, buying the extra 200 lm/ft needed when curtains are closed and the room appears dimmer than the corridor.

Headboard back-lighting

A 45° angled “asymmetric” track throws light forward onto the artwork, not onto the pillow. Mount directly to the 16-gauge steel stud with self-drilling screws; no wood blocking required. Fire-rated 1-hour assemblies are maintained because the track is only 8 mm thick and does not penetrate the full 15 mm Type-X board.

Corridor skirting

Low-glare wall-wash is achieved with a 10 × 17 mm “plaster-in” track set 100 mm above finished floor. Pair with a 24 V, 180 lm/ft, 2200 K LED for a “candle-in-a-tunnel” effect that guides guests without triggering circadian wake-up at 2 a.m. IP20 is fine; janitorial hoses never reach that high.

Ballroom coffer

Continuous 5 m lengths are possible if you switch to 24 V and use a 2.5 mm² conductor inside the track—voltage drop stays under 5 % at 8 A. Specify a “drywall flange” track so the GC can mud right up to the aluminum; no shadow gaps that collect plaster dust. Dim with DALI-2; the extrusion keeps the LED below 55 °C so color shift is < 2 SDCM over 15 000 h.

- Offices: Circadian Metrics on a Monday Morning

Desk-edge task

A 45° asymmetric track under the shelf eliminates reflected glare on laptop screens (UGR < 19). Use a micro-prismatic lens that peaks at 30 cd/klm; power at 6 W/m in 4000 K, 80 CRI. The track is anodized at 15 µm so coffee spills and cleaning solvents don’t etch the finish.

Pendant indirect

Suspend 40 × 40 mm “wide-wing” track with aircraft cable; the large surface area keeps junction temperature at 50 °C while running 14 W/m upward for 300 lx on the ceiling. This raises mean cylindrical illuminance (Ez) by 120 lx, the cheapest circadian boost you can buy without rewiring the ceiling grid.

Meeting-room halo

Recess a 20 × 20 mm track into 12 mm MDF ceiling trim; the frosted lens hides individual LEDs when the 4K camera pans across the room. Specify a flat PCB with 180 LEDs/m so the halo is pixel-free even at 0.5 m viewing distance—important for VC background lighting.

Emergency egress

Use a fire-rated 1-hour track with integrated 3.6 V battery pack every 2 m. The aluminum extrusion doubles as a heat shield, keeping the battery below 60 °C in a fire. Test to IEC 60598-2-22; the same track carries normal 24 Vdc during non-emergency mode, so no duplicate channel is needed.

- Pools & Spas: Where Chlorine Meets Aluminum

Underwater bench

Only IP68 tracks with 2-bar pressure rating belong here. Specify 316 stainless steel end-caps and two-part silicone gasket rated for 100 °C (because heaters fail). Drive at 12 Vdc for swimmer safety; use an RCD < 30 mA. The track is screwed into stainless inserts poured in the gunite; thermal cycling is handled by a 3 mm expansion gap every 2 m filled with neutral-cure silicone.

Ceiling above water

IP54 is acceptable if the track is > 2.3 m above pool deck. Use a 45° asymmetric lens to throw light toward the lane markers, eliminating ceiling reflection on the water surface that blinds lifeguards. Anodize at 25 µm (marine grade) and specify a polyester powder coat; chlorine off-gas will pit standard 15 µm anodizing in 18 months.

Perimeter overflow channel

A narrow 8 × 8 mm track fits under the stainless grate. Lens is UV-stabilized polycarbonate; ordinary PMMA turns yellow after 2000 h of combined UV and chloramine exposure. Power from a remote 24 V supply in a NEMA 4X enclosure; the track itself is IP67, but splashing water carries chlorides that would wick into PCB edges if IP65 were used.

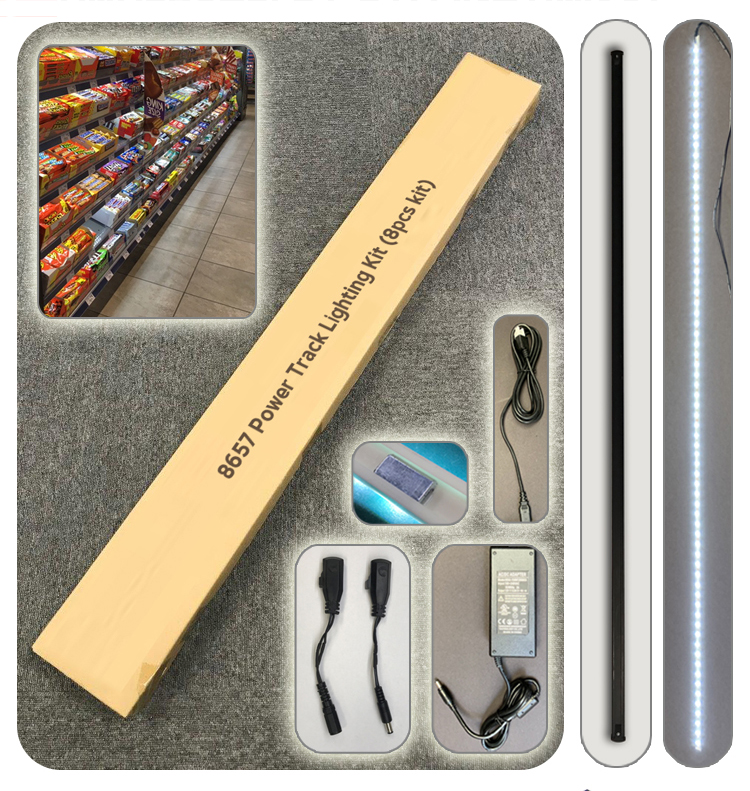

- Retail: Making Merchandise Look Expensive

Shelf-front light-bar

A 15 × 7 mm “lipstick” track clips to the glass shelf; 3000 K, 95 CRI, 1 × 2 binning so the diamond fluorescence is consistent across the case. The track is supplied in 3 m lengths—jewelers hate visible joints. Use a 30° lens for 1:3 contrast ratio (merchandise : background) which studies show raises perceived value by 18 %.

Window display

Surface-mount track with a 45° snoot eliminates street glare at night. Specify 4000 K to balance against 2000 K sodium streetlights; the track’s black anodized finish disappears against matte-black window mullions. Integrate DMX so the store manager can “warm-sweep” the color temperature from 4000 K to 2700 K at closing time—an inexpensive circadian cue that reduces staff headache complaints.

- Healthcare: MRI Suite to NICU

MRI room

All ferrous metals are banned. Use a 100 % aluminum track with brass inserts and non-magnetic stainless screws. The LED is 24 Vdc, flicker-free (< 1 % at 1000 Hz) because patients may be sedated and EEG artifacts must be < 10 µV. The track is recessed into RF-shielded drywall; the lens overlaps the copper mesh by 5 mm so no RF leak occurs.

NICU toe-kick

2700 K, 80 CRI, < 50 lx at crib height. A micro-prismatic lens in a 10 × 10 mm track eliminates blue-spike at 450 nm that would suppress melatonin in pre-term infants. The track is sealed IP54 so vaporized isopropyl alcohol during cleaning does not reach the PCB.

- Food & Beverage: Cold Room to Sushi Counter

Walk-in cooler

LED efficacy drops 1 % per °C below 25 °C. Use a 20 × 30 mm track with built-in 2 W/m silicone heating trace; thermostat kicks in at 5 °C so the LED stays at 10 °C, efficacy only 6 % down instead of 15 %. Lens is food-grade polycarbonate with anti-fog coating; NSF splash-zone approved.

Sushi counter

2700 K, 95 CRI, R9 > 90 so raw tuna looks red, not brown. Track is IP67 with rounded edges—health department will reject any profile that can accumulate rice. Mount 300 mm above counter; 25° lens gives 800 lx on fish surface, 200 lx on customer side, the 4:1 contrast that chefs insist on.

Installation Checklist (Universal)

1. Thermal path: 2 mil thermal tape or 0.5 W/m·K gap filler between PCB and extrusion—non-negotiable for warranty.

2. Earth bond: If track length > 2 m, bond both ends to building earth; aluminum is not ferrous but it is conductive.

3. Expansion: Allow 1 mm per meter at 40 °C ΔT; use sliding end-caps, not fixed.

4. Wiring: 24 V for runs > 5 m; 12 V only for wet-location or battery-backup zones.

5. Lens cleanability: Specify anti-static coating; otherwise dust attraction will be visible on down-lighting in < 3 months.

Takeaway

The LED strip track is no longer a cosmetic after-thought; it is the thermal, optical, and regulatory backbone of the installation. Match the extrusion family to the application scenario first, then choose the LED second. Do it the other way around and you will own the callback.

Why Choose Seven Colors Lighting

In today’s competitive lighting market, procurement challenges can derail project timelines and budgets. Supply chain volatility, inconsistent quality, and hidden costs from fragmented sourcing often force businesses to navigate complex trade-offs. Seven Colors Lighting, part of Maxtop Tech, addresses these challenges through a uniquely integrated manufacturing ecosystem designed for reliability and efficiency. Our approach isn’t just about selling products—it’s about building a partnership that scales with your needs while eliminating traditional procurement bottlenecks.

At the core of our model is a network of over 1,000 coordinated factories spanning multiple regions. This isn’t merely a quantity metric; it’s a strategic advantage. Each facility operates under unified quality protocols, standardized production processes, and centralized oversight, ensuring consistency whether you’re ordering 100 units or 100,000. This scale allows us to handle diverse product requirements—from specialized architectural lighting to high-volume commercial fixtures—without compromising on precision. Crucially, the network’s geographic diversity mitigates single-point failures, ensuring continuity even during regional disruptions. For clients managing multi-site projects or fluctuating demand, this means predictable output and reduced risk of delays.

Factory-direct pricing is another cornerstone of our value proposition. By eliminating intermediaries and maintaining direct control over the supply chain, we pass tangible savings to our partners. This isn’t about cutting corners—it’s about optimizing every layer of production. Our vertically integrated structure allows us to source raw materials efficiently, streamline logistics, and reinvest savings into advanced manufacturing technologies. The result is competitive pricing without sacrificing quality or innovation. Clients consistently report 15-25% cost reductions compared to traditional distributor models, freeing up budget for project enhancements or scalability.

Speed is equally critical in modern procurement. With our coordinated factory network strategically positioned across key production hubs, we minimize lead times without compromising on craftsmanship. Our logistics team leverages real-time data to optimize routing, inventory allocation, and shipping schedules, ensuring orders move seamlessly from production to delivery. For urgent projects or seasonal demand spikes, this translates to industry-leading turnaround times—often 30% faster than market averages. Whether you’re completing a tight commercial retrofit or launching a new retail line, our ability to deliver quickly empowers you to meet deadlines confidently.

Partnering with Seven Colors Lighting means more than accessing products—it’s about integrating a resilient, cost-efficient supply chain into your operations. Our 1,000+ coordinated factories, factory-direct pricing model, and rapid delivery capabilities work in concert to reduce complexity, lower costs, and accelerate time-to-market. For businesses seeking a reliable, scalable lighting partner, we invite you to explore how our ecosystem can support your unique goals. Contact us today to discuss your next project and experience the difference of a truly integrated solution.

Contact Us

Ready to start your project? Contact Seven Colors Lighting (Maxtop Tech) today.

- Email: info@maxtoptek.com

- Tel/Fax: +86-0760-85320448

- Address: 5th Floor, NO.6 Fourth Street, Dongpai Xi Road, Xiaolan Town, Zhongshan City, China

💡 LED Power Calculator

Estimate the power supply needed for your project.

Skype Me

Skype Me