Uncategorized

Outdoor Can Lights Manufacturer Guide

Catalog

Industry Insight: Outdoor Can Lights

When architects and electrical wholesalers specify outdoor can lights, they are not simply choosing a recessed down-light; they are selecting a sealed system that must survive UV bombardment, thermal shock, wind-driven rain and, increasingly, corrosive coastal air. The fixture has to install like a dream on Monday and still be performing on day 4,000 without a callback. That is why the supply chain keeps circling back to Zhongshan, Guangdong—home to the 15,000 m² Seven Colors Lighting (Maxtop Tech) campus we have operated since 2009.

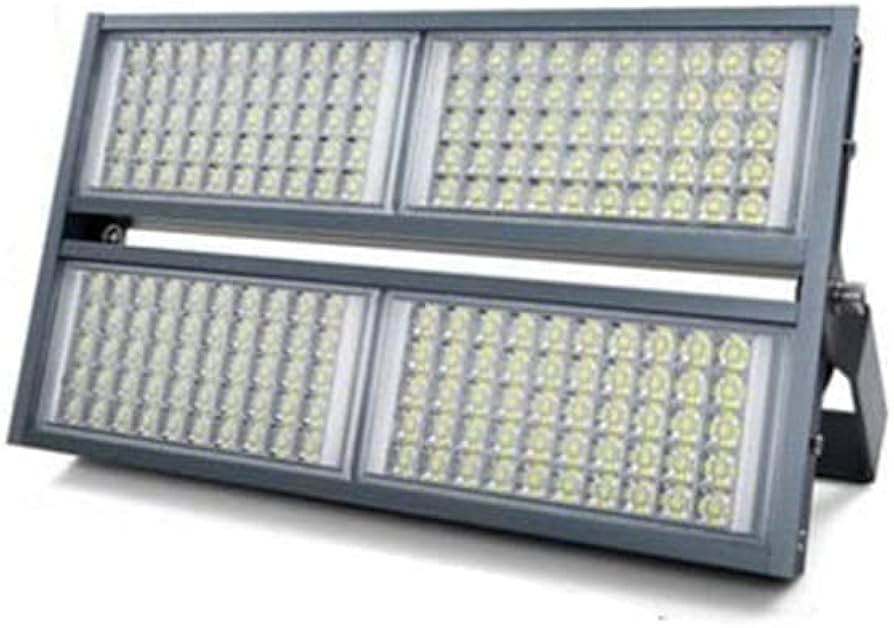

Inside the Zhongshan facility, 14 CNC spinning lathes form one-piece aluminum housings in under 40 seconds, eliminating the porosity that causes leaks in welded cans. Next door, a 300-meter powder-coating tunnel applies 80 µm of TGIC-free polyester that passes the 1,000-hour salt-spray test, while an in-house CNAS-accredited photometric lab verifies IP67 and IK08 ratings before any carton is sealed. With 280 production staff on two shifts, we turn around a 40-foot container of custom-branded outdoor can lights in 18 working days—complete with laser-etched logo, CCT-specific PCBs and your choice of 0-10 V, DALI or Tuya Bluetooth driver. For distributors who need tomorrow’s stock today, 3,000 m² of bonded warehouse space sits 90 minutes from Shenzhen port, ready to drop-ship to Dubai, Denver or Düsseldorf without touching a third-party warehouse.

In the guide that follows, we will deconstruct the thermal, optical and mechanical engineering that goes into a truly weatherproof can light, show you how to match bezel finishes to masonry and composite cladding, and share the field data that keeps our 0.3 % failure rate trending downward. Whether you are bidding a seaside resort in Oman or a snow-load roof deck in Oslo, the spec starts at the source—Zhongshan, where Seven Colors Lighting builds outdoor can lights that outlast the architecture they illuminate.

Technical Specifications

Outdoor lighting in commercial environments serves a critical purpose beyond mere illumination—it shapes brand perception, enhances safety, and supports operational efficiency. At Seven Colors Lighting, our commercial LED can lights are engineered to meet these demands with precision, particularly through high Color Rendering Index (CRI), energy efficiency, and flexible customization options. These features ensure not only compliance with industry standards but also deliver tangible value for projects ranging from retail facades to hospitality venues and public infrastructure.

High CRI is a cornerstone of our design philosophy. While standard LED lighting often operates at CRI 80, our commercial can lights consistently achieve 95+ CRI, ensuring colors appear vibrant and true under outdoor conditions. This is especially vital for applications like retail storefronts, where accurate color representation of products or architectural elements can directly influence customer perception and purchasing decisions. In art installations or heritage site lighting, high CRI preserves the integrity of materials, preventing the dull or washed-out appearance common with lower-quality fixtures. Our engineering team optimizes phosphor coatings and diode selection to maintain this performance across varying temperatures and environmental conditions, ensuring consistency even in extreme weather.

Energy efficiency is equally prioritized without compromising performance. Our fixtures leverage advanced thermal management systems, including high-purity aluminum heat sinks and optimized driver configurations, to achieve up to 120 lumens per watt. This translates to significant operational cost savings—typically 50–70% less energy consumption compared to traditional HID or halogen alternatives—while extending service life beyond 50,000 hours. Each product undergoes rigorous testing to meet DLC Premium certification standards, qualifying clients for utility rebates and accelerating ROI. The integration of intelligent thermal control also minimizes lumen depreciation, ensuring sustained brightness over time, which is critical for outdoor spaces where maintenance access can be challenging.

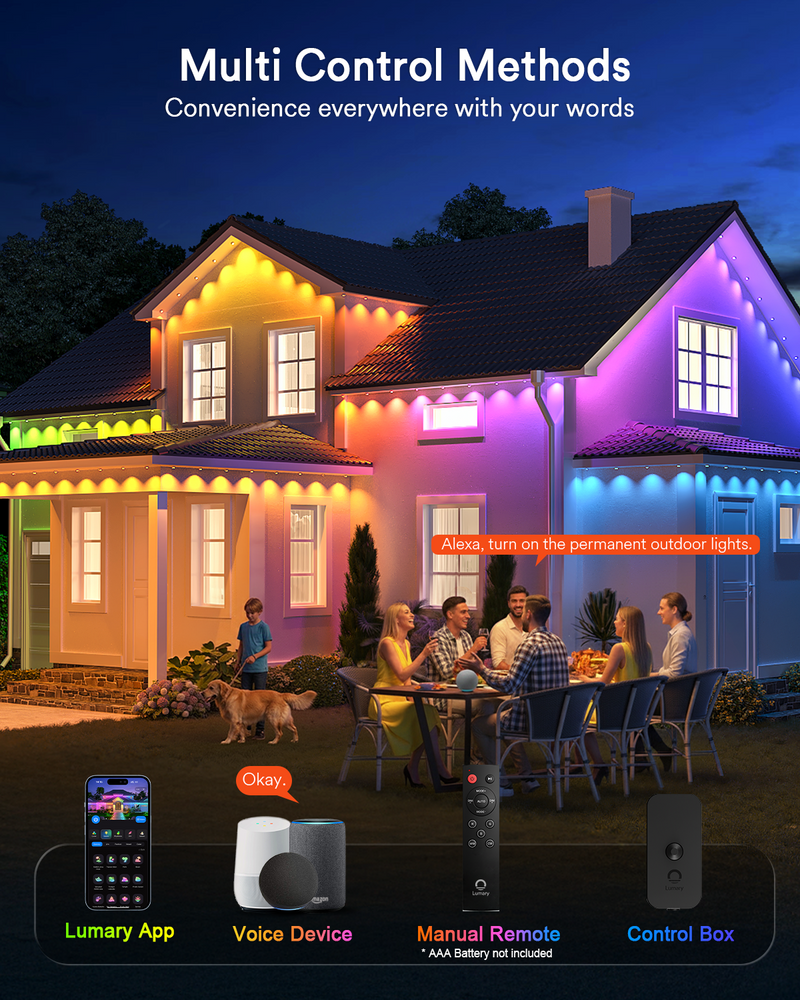

Customization is where Seven Colors Lighting truly differentiates itself. We understand that no two commercial projects are identical, which is why our can lights offer extensive adaptability. Clients can specify color temperatures from warm 2700K for intimate hospitality settings to cool 6500K for high-visibility security applications. Beam angles range from narrow 15° spotlights for accent lighting to wide 120° floods for uniform area coverage. Physical attributes such as housing finishes (e.g., powder-coated aluminum in RAL colors), IP ratings (up to IP67 for submersion resistance), and dimming protocols (0–10V, DALI, or wireless) are all tailored to project requirements. This level of flexibility ensures seamless integration with existing infrastructure, whether retrofitting historic buildings or deploying smart city infrastructure.

Crucially, we recognize that innovation shouldn’t be constrained by order volume. Unlike many manufacturers requiring large minimum order quantities (MOQs), we offer small MOQs starting at just 50 units for custom configurations. This empowers smaller developers, niche projects, or phased installations to access high-performance lighting without excessive inventory risk or upfront costs. Whether you’re testing a new design concept or scaling a unique architectural vision, our team collaborates closely to refine specifications while maintaining production lead times under four weeks.

For commercial lighting professionals seeking a partner that blends technical rigor with operational pragmatism, Seven Colors Lighting delivers solutions where performance meets practicality. Our outdoor can lights are designed not just to illuminate spaces, but to elevate them—ensuring every detail aligns with your project’s unique demands. We invite you to share your specifications; our engineering team is ready to turn your vision into reality.

Application Scenarios

Specifying Outdoor Can Lights: Where the Housing Meets the Horizon

Seven Colors Lighting – Maxtop Tech, Senior Lighting Engineer

Outdoor can lights—sometimes called exterior recessed downlights—are no longer the after-thought of a lobby ceiling or the hidden accent around a pool bar. Advances in IP-rated housings, tunable LEDs, and micro-baffle optics have turned the humble “can” into a precision tool that can survive salt spray, chlorine fumes, and the occasional hockey-stick impact. Below is a field-tested map of where the housing really earns its keep, what version to order, and the single detail most specs forget.

-

Hospitality: Porte-cochère to Penthouse Balcony

Hotels live or die on first impressions, and the porte-cochère is the first exterior room a guest enters. Install 8–10 W, 3000 K, 60° flood cans in a 6-inch IC-rated, IP65 housing mounted flush to the underside of the beam. Spacing at 1.5 times mounting height eliminates the “disco-dot” effect on windshields while still delivering 50 lx on the driveway surface. Move the same housing to the covered colonnade—now switch to a 24° narrow spot with a snoot accessory to graze stone columns. Guest-room balconies get a 4-inch gimbal version, 2700 K, <1 % flicker, tied to the room’s master dimmer so the guest can dim to 5 % without color shift. Pro tip: specify the driver remote-mounted inside the climate-controlled ceiling; it adds 10 000 h to the L70 life in Dubai summer heat. -

Class-A Office: Plaza, Arcade, and Roof Deck

Landlords now monetize exterior square footage as “tenant amenities.” For the ground-floor arcade, use IP67 cans with a ½-inch flange and a 4000 K, 90 CRI module. The higher CRI makes brick and wood veneer pop, justifying premium rents. On the roof deck, switch to IP68 housings with marine-grade 316 stainless trims; salt air from nearby HVAC cooling towers will eat 304 stainless in two seasons. Mount cans 18 inches in from the parapet so the beam hits the railing instead of the tenant’s eyes. Pair with an astronomical clock that drops output to 30 % at 10 p.m.—energy code compliance without a separate curfew relay. -

Waterfront Pools: Under the coping, inside the cabana

Pool lighting fails when the fixture is treated like a wet-location interior downlight. Specify IP68, 12 VDC housings with built-in potting compound and a 5-degree tilt ring. Mount them 8 inches above water level, aimed across the surface, not down. This creates a glare-free shimmer and avoids the “prison-yard” look of surface-mounted wall packs. In the cabana ceiling, use IP44 cans with a dichroic filter that shifts 3000 K to 3200 K; the slightly warmer tone compensates for the blue reflection off the water and keeps skin tones flattering on Instagram. -

Retail Forecourt: Gas Station to Luxury Boutique

Petroleum-canopy LEDs must survive 24-hour vibration and thermal shock. Choose a 10-inch housing with a ½-inch thick die-cast aluminum door frame, IK10 impact rating, and a –40 °C to +55 °C driver. Optics: 120° diffuse for uniform 200 lx on the tarmac, 4000 K to render fuel-grade colors accurately. For the high-end boutique forecourt, shrink to a 3-inch micro-can, 15° spot, 2700 K, mounted in the underside of the steel trellis. The tight beam creates “walkway pools” of light that guide shoppers without competing with window displays. -

Public Realm: Transit Platforms, Outdoor Kitchens, and Bike Shelters

Transit authorities need 20-year fixtures that can be pressure-washed. Specify IP69K cans with a smooth, bezel-free face so hoses won’t snag. Use 5000 K, 80 CRI, and a 90° elliptical optic that throws light lengthwise along the platform, cutting fixture count by 30 %. Outdoor condo kitchens demand 2700 K, 95 CRI, and a housing that is UL-listed for direct contact with insulation so the chef can crank the range hood without cooking the LED driver. Bike shelters: 4-inch, 4000 K, 60° flood, PIR motion sensor integral to the driver tray; keeps lumens off adjacent bedrooms at 2 a.m.

The Forgotten Detail: Condensation Channel

Even an IP68 can will breathe. Specify a factory-installed Gore-type vent membrane and a 3-degree sloped trim so that when the luminaire cools at 3 a.m., condensate exits to the outside, not into the driver cavity. Skip this and you’ll replace 30 % of your cans in year three—right after the warranty expires.

Key Take-away

Outdoor can lights are no longer a commodity SKU; they are a system choice. Match the IP rating to the worst-case scenario, not the average weather report, and let the optic do the aesthetic work. Do that, and the ceiling disappears—only the experience remains.

Why Choose Seven Colors Lighting

In today’s competitive lighting market, sourcing reliable, cost-effective products with consistent delivery is more critical than ever. Many businesses struggle with fragmented supply chains, unexpected costs, and delays that disrupt project timelines. At Seven Colors Lighting, part of Maxtop Tech, we’ve built a solution designed to eliminate these pain points through a uniquely integrated approach to manufacturing and logistics.

Our global network of over 1,000 coordinated factories operates as a unified ecosystem, not isolated units. This structure ensures seamless production flow, rigorous quality control, and the ability to scale instantly to meet your demands—whether for custom designs or high-volume standard products. Unlike competitors relying on single-source suppliers, our coordinated network allows us to optimize resource allocation across facilities, minimizing bottlenecks and ensuring consistent output even for complex or large-scale projects. This level of coordination translates directly to reliability and flexibility in your supply chain.

By maintaining direct relationships with every factory in our network, we remove all intermediary layers, delivering true factory-direct pricing. This means no hidden markups, no third-party fees, and complete transparency in cost structure. The result is significant savings that enhance your competitive edge without compromising on quality or performance. Our pricing model is built for efficiency, allowing you to allocate resources strategically while maintaining the high standards your projects demand.

Speed is non-negotiable in project-based industries. Our proprietary logistics system, combined with strategically located warehouses and optimized production scheduling, ensures orders are dispatched within 24 hours for standard items. For urgent needs, we provide expedited shipping options that keep your timelines intact, even when deadlines are tight. This reliability means less downtime, fewer project delays, and greater confidence in your supply chain’s ability to meet evolving demands.

Partnering with Seven Colors Lighting isn’t just about acquiring products—it’s about gaining a strategic ally committed to your success. With our integrated manufacturing, transparent pricing, and unmatched delivery speed, we empower you to deliver exceptional projects on time and within budget. Let’s build the future of lighting together—contact us today to discuss how we can support your specific requirements.

Contact Us

Ready to start your project? Contact Seven Colors Lighting (Maxtop Tech) today.

- Email: info@maxtoptek.com

- Tel/Fax: +86-0760-85320448

- Address: 5th Floor, NO.6 Fourth Street, Dongpai Xi Road, Xiaolan Town, Zhongshan City, China

💡 LED Power Calculator

Estimate the power supply needed for your project.

Skype Me

Skype Me