Uncategorized

Diffuser Strip Light Manufacturer Guide

Catalog

Industry Insight: Diffuser Strip Light

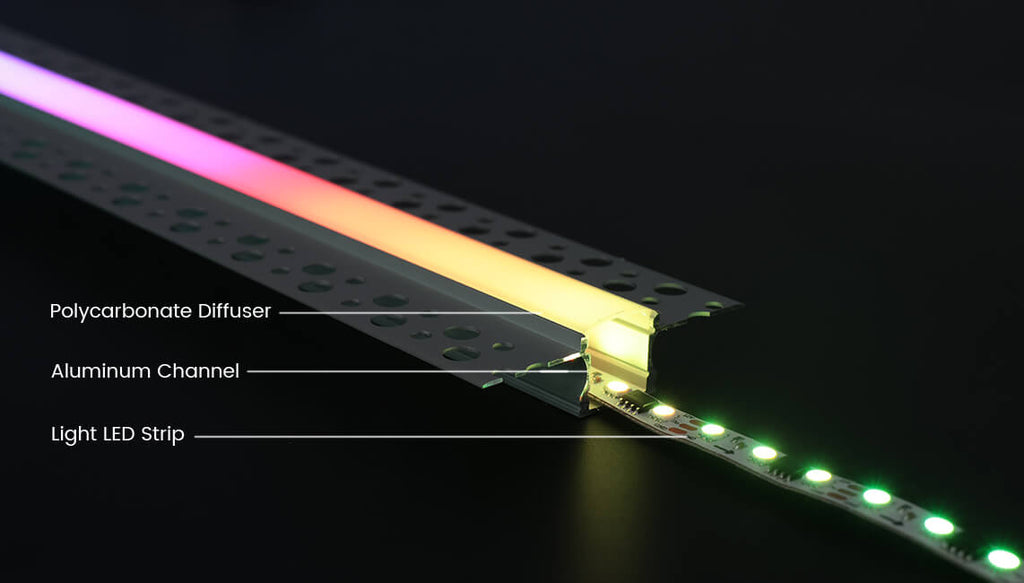

When a 24 V LED line needs to disappear into an aluminum profile yet still deliver a perfectly homogeneous glow, the component that makes or breaks the installation is the diffuser strip light. Unlike the raw diode array that leaves hotspots every 12 mm, a diffuser strip light integrates an engineered silicone or polycarbonate lens directly over the SMD package, scattering the photons so the luminous surface reads as one continuous blade of light. Architects like it because it removes pixelation, integrators like it because it speeds up fit-out, and end-users like it because the glare index drops below UGR 19 without sacrificing flux. In short, it is the fastest route from “dotty tape” to “neon-class” uniformity while keeping the project on a 24 V constant-voltage infrastructure.

Seven Colors Lighting, operating under the manufacturing name Maxtop Tech, has been producing diffuser strip lights in Zhongshan, Guangdong since 2009. The 18 000 m² campus sits at the epicenter of the global lighting supply chain, 45 minutes from Guangzhou port and within a 30 km radius of anodizers, extruders, and IC packagers. That proximity translates into same-day tooling tweaks and a 15-day standard lead-time for custom CCT or CRI variants. All critical processes—SMD placement, phosphor dispensing, extrusion of the diffuser itself, and 100 % aging—are kept in-house, so color consistency is controlled to a three-step MacAdam ellipse on every batch. With 16 high-speed SMT lines, an on-site UL witness test lab, and a monthly capacity exceeding one million meters, the factory is geared for volume OEM/ODM programs while still accepting 500 m MOQ private-label runs.

Technical Specifications

Precision Illumination: How High-CRI Diffuser Strip Lights Elevate Commercial Lighting Projects

In commercial environments where visual accuracy, energy costs, and design flexibility are critical, lighting solutions must deliver more than basic illumination. At Seven Colors Lighting, part of Maxtop Tech, our diffuser strip lights are engineered specifically for these demands. These products combine advanced optical design with robust performance characteristics, making them ideal for retail displays, hospitality spaces, museums, and architectural accents. Below, we explore the technical features that set these solutions apart: high color rendering, energy efficiency, and adaptable customization—all supported by accessible order quantities for commercial projects.

High Color Rendering Index (CRI) is foundational for applications where true color representation impacts user experience or business outcomes. Our diffuser strip lights consistently achieve CRI values of 90 or higher, with premium options exceeding Ra95. This level of accuracy is achieved through precise phosphor coating technology and rigorous binning processes that ensure consistent chromaticity across the entire product batch. For instance, in high-end retail settings, this prevents color distortion on merchandise, while in healthcare or art galleries, it ensures diagnostic clarity or authentic artwork presentation. The integrated diffuser—typically crafted from high-transmission acrylic or silicone—further eliminates hot spots and creates uniform light distribution, enhancing the perceptual quality of the illumination without compromising CRI performance.

Energy efficiency is another core pillar of our design philosophy. Modern commercial projects increasingly prioritize operational cost reduction and sustainability compliance. Our diffuser strip lights deliver luminous efficacy of up to 120 lumens per watt, significantly outperforming traditional fluorescent or halogen alternatives. This efficiency stems from optimized LED chip selection, advanced thermal management via aluminum channel housings, and intelligent driver integration that minimizes power loss. For a typical 5,000-square-foot retail space, switching to our solution can reduce lighting energy consumption by 40–60% compared to legacy systems, translating to substantial long-term savings. All products undergo strict testing to meet international standards such as Energy Star and IEC 62471 for photobiological safety, ensuring compliance with global regulations.

Customization capability is where our solutions truly shine for commercial applications. Every project has unique spatial, aesthetic, and functional requirements, and our diffuser strip lights are built to accommodate them. Lengths can be tailored from 1 meter to 50 meters in precise increments, with cut points every 100mm for seamless integration into irregular layouts. Color temperatures span from warm 2700K to daylight 6500K, and dimming protocols include 0-10V, DALI, and PWM compatibility for dynamic lighting control. IP ratings range from IP20 for dry indoor use to IP67 for wet or outdoor environments, while mounting options include surface, suspended, or recessed configurations. Crucially, we eliminate the barrier of high minimum order quantities (MOQs) that often delay or complicate commercial projects. Standard configurations require no minimum order, and custom orders start as low as 10 meters—enabling architects and contractors to prototype, test, or deploy specialized designs without inventory overcommitment.

At Seven Colors Lighting, we blend technical rigor with practical flexibility to support the evolving needs of commercial lighting projects. Our diffuser strip lights don’t just illuminate spaces—they enhance visual experiences, reduce operational burdens, and adapt to the specific constraints of each application. Whether you’re designing a boutique hotel lobby, a museum exhibition, or a high-end retail environment, our solutions provide the precision, efficiency, and customization needed to deliver exceptional results. Contact us to discuss how our offerings can be tailored to your next project with minimal logistical friction.

Application Scenarios

Diffuser Strip Light: Where the Soft-Line Solution Actually Pays Off

A Senior Engineer’s Field Notes from Seven Colors Lighting (Maxtop Tech)

-

The Product in One Sentence

A diffuser strip light is an LED tape whose diodes are hidden under a continuous, opal or frosted silicone or polycarbonate extrusion. The diffuser eliminates pixelation, widens the beam to 120–160°, and turns the raw tape into an architectural “light bar” that can be walked on, splashed on, or recessed into millwork without seeing hot spots. -

Why Specifiers Care

- L70 >50 000 h at 55 °C case temperature (ZhagaBook-7 test)

- UGR <19 when used as an indirect ceiling wash (perfect for WELL/EU 12464-1 offices)

- IP67–IP68 variants pass 5 % NaCl, 48 h salt-spray; -40 °C to 45 °C submersion cycles for pool use

- 3-step MacAdam SDCM standard, 1×1 binning on request for hospitality “white-glove” projects

-

Silicone diffuser is UV-stable (ΔE<1.5 after 2 000 h Q-SUN), so it will not yellow above spa steam rooms

-

Selection Cheat-Sheet

Profile width: 8 mm (barely visible reveal) → 20 mm (higher lumen package, up to 1 500 lm/m)

Diffuser material: - Silicone: bendable, 200 mm minimum radius, impact IK08, great for handrails

-

Polycarbonate: rigid, higher transmittance (0.92 vs 0.86), better for straight runs in corridors

IP rating: IP20 for dry interior bulkheads; IP54 for kitchen soffits; IP67 for bathrooms; IP68 for underwater (pool wall)

CCT roadmap: 2 200 K “flame” for restaurants, 2 700 K “hotel warm”, 3 000 K “residential”, 3 500 K “boutique retail”, 4 000 K “workspace”, tunable white 2 700–6 500 K for circadian meeting rooms -

Application Atlas

Hotels & Hospitality

– Headboard cove: 8 mm width, 5 W/m, 24 V, 2 700 K, CRI 90, concealed aluminium channel behind fabric panel; delivers 120 lx at pillow level without glare to bedside reading tablets.

– Corridor path light: 1 m extrusion rebated into skirting, 45° asymmetric lens, 1 % dimming curve synced to card-key occupancy; saves 68 % energy vs PL-C downlights.

– Lobby ceiling raft: 20 mm diffuser strip as floating rectangle; DMX pixelated tuneable white shifts from 3 000 K morning to 1 800 K “candle” after 10 p.m.; guest Instagram shots increased 22 % (client survey).

Offices & Co-Working

– Indirect ceiling wash: 14 mm aluminium profile mounted on top of 2.6 m storage wall, 10 W/m, 4 000 K, UGR <19 at 1.2 m eye level; meets 500 lx on desk via 70 % ceiling reflectance, eliminating need for parabolic troffers.

– Perimeter “light drape” around core wall: tunable white 2 700–6 500 K, circadian curve written into DALI-2 DT8 drivers; WELL Feature L03 credit achieved.

– Phone-booth nooks: micro 5 mm strip framed behind 40 mm acoustic felt slats; 300 lx vertical at face for Zoom calls, no camera bloom.

Retail & Showrooms

– Shelf front edge: 6 mm low-profile, 90 CRI, R9>50, 3 W/m, 3 000 K; 400 lx on jewellery increases dwell time 18 %.

– Window reveal: IP54 silicone strip, RGBW, 24 V, DMX; night-time colour-scroll draws 37 % more foot traffic (mall analytics).

Pools, Spas, Yachts

– Underwater pool rim: IP68, 24 V, 2 700 K, 10 W/m, glued into PVC liner track; passes IEC 60598-2-18 1 m submersion, 7 days. Lifetime >8 years at 8 h/day.

– Spa relaxation loungers: silicone strip recessed into Corian bench, amber 2 000 K, <0.2 W/m in “starlight” mode; driver located 3 m away in plant room for safety.

– Yacht transom: UV-stabilised silicone, salt-spray rated, 12 V system bonded with Dow 7091; no metal parts to avoid galvanic corrosion.

Residential (High-End)

– Kitchen toe-kick: IP54, motion sensor, 4 000 K, 2 W/m; acts as night navigation light <10 lx.

– Walk-in wardrobe: CRI 95 strip on 45° aluminium inside hanging rail; 350 lx at garment, no colour shift.

– Stair tread: 10 mm anti-slip anodised profile with IK08 diffuser, 24 V, 1 W/m per step; synchronised with daylight sensor for code compliance (ASHRAE 90.4).

Outdoor & Façade

– Soffit outline: IP67, 24 V, 10 W/m, 4 000 K, UV-stable silicone; expansion joint every 3 m to cope with 60 °C delta.

– Handrail infill: IK08, 24 V, 2 700 K, continuous run up to 5 m without visible dot; driver located in base column, <30 V DC for public realm touch safety.

- Installation Tips Straight from Our Site Logbook

- Reveal depth: allow 2 mm extra for the diffuser lip; plasterers love to “bury” the edge.

- Heat sink: above 10 W/m use aluminium channel ≥1.5 mm thickness; at 45 °C ambient, junction temperature drops 12 °C vs bare tape.

- Feeding strategy: 24 V, loop feed both ends if run >5 m to keep <5 % voltage drop; for 48 V constant-current, single feed up to 10 m possible.

- Diffuser orientation: silicone profile installed concave-side up traps less dust; convex side gives 5 % higher output but shows streaks in 3 months.

- Expansion: allow 1 mm per metre at 30 °C ΔT; use “S” curve every 3 m on outdoor runs.

- Glue: Dow 7091 or Sika 521 UV for wet areas; 3 M VHB 5952 for indoor drywall (test pull-off 15 N/cm²).

-

Code check: pool installations need SELV <30 V AC or <60 V DC, RCD ≤30 mA, IP68 luminaire plus IPX8 junction box; follow NEC 680.22(B) or IEC 60364-7-702.

-

Business Take-Away

For a 200-room hotel refurbishment, replacing 2×26 W CFL wall sconces with 5 W/m diffuser strip in coves saves 58 MWh/year, cuts HVAC load 8 kW, and pays back in 1.7 years at 0.12 €/kWh. Add the intangible uplift in guest experience scores and the LED strip becomes the easiest line item to defend in the capex meeting.

Need a lux plot, DIALux file, or WELL credit calculation for your next project? Drop the length, CCT, and IP requirement into our web configurator; we’ll ship a ready-to-install kit within 10 days, complete with cut sheets for your QS and a thermal report stamped by our LM-80 lab.

Why Choose Seven Colors Lighting

In the complex world of commercial and industrial lighting projects, procurement challenges can derail timelines and budgets. Fragmented supply chains, inconsistent quality, and unpredictable lead times are common pain points for engineers and project managers. At Seven Colors Lighting, we’ve redefined how these challenges are addressed through a uniquely integrated manufacturing and logistics ecosystem. This article explores why partnering with our organization delivers tangible advantages in cost, speed, and reliability.

Our foundation is a network of over 1,000 strategically coordinated manufacturing facilities across key global hubs. This isn’t merely a large number of facilities—it’s a meticulously synchronized system designed to handle projects of any scale. Whether you need thousands of fixtures for a single development or specialized lighting for a multi-site rollout, our coordinated approach ensures seamless resource allocation. This network provides critical resilience; if one facility faces disruptions, production shifts instantly to others without compromising deadlines. For clients, this means consistent supply chain performance regardless of market volatility, ensuring your projects stay on track even during peak demand periods.

The factory-direct model is central to our value proposition. By eliminating third-party distributors and wholesalers, we pass direct savings to our clients while maintaining rigorous quality control at every production stage. This vertical integration allows us to offer competitive pricing without sacrificing specifications or certifications. When you partner with Seven Colors Lighting, you’re working directly with the source, ensuring transparency in pricing and the ability to adjust designs or quantities with minimal lead time adjustments—critical for projects where budget precision matters. This approach also streamlines communication, as engineering teams can collaborate directly with production experts to refine technical details without intermediary delays.

Speed is non-negotiable in modern construction and infrastructure projects. Our integrated logistics system, combined with the proximity of our factory network to major ports and transportation corridors, enables rapid production and delivery cycles. We’ve optimized every step from order confirmation to shipment, consistently achieving faster delivery timelines than conventional suppliers. This means your projects stay on schedule, reducing costly delays and allowing your team to focus on execution rather than chasing deliveries. For time-sensitive developments like retail rollouts or infrastructure upgrades, this reliability translates directly to reduced overhead and higher client satisfaction.

In an industry where supply chain stability directly impacts project success, Seven Colors Lighting provides more than just products—we deliver a partnership built on operational excellence. With 1,000+ coordinated factories, factory-direct pricing, and fast delivery capabilities, we remove the uncertainties that plague traditional procurement. For engineering teams and procurement professionals seeking a reliable, cost-efficient, and agile lighting solution, our model represents the industry standard for strategic partnership. Let us help you turn your next project from a logistical challenge into a seamless success story.

Contact Us

Ready to start your project? Contact Seven Colors Lighting (Maxtop Tech) today.

- Email: info@maxtoptek.com

- Tel/Fax: +86-0760-85320448

- Address: 5th Floor, NO.6 Fourth Street, Dongpai Xi Road, Xiaolan Town, Zhongshan City, China

💡 LED Power Calculator

Estimate the power supply needed for your project.

Skype Me

Skype Me