Uncategorized

Led Module Factory Manufacturer Guide

Catalog

Industry Insight: Led Module Factory

Inside the LED Module Factory: How Seven Colors Lighting (Maxtop Tech) Turns 15 Years of Zhongshan Expertise into Scalable, Specification-Grade Solutions

When a lighting brand, fixture OEM, or project house goes hunting for an LED module partner, the shortlist almost always lands on one city: Zhongshan. Home to the densest lighting supply chain on the planet, the Guangdong hub ships one in every three LED products exported worldwide. Yet even here, factory capability varies wildly—from garage-level workshops to fully robotized campuses. Seven Colors Lighting (Maxmax Tech), founded in 2009, has spent the last 15 years moving itself firmly toward the latter end of that spectrum. The result is a 28,000 m² campus in Guzhen Town that produces 3.2 million LED modules per month, all engineered for the repeatability, documentation, and certification demands of professional B2B customers.

What separates a “module supplier” from a true module factory is the ability to control every variable that influences lumen maintenance, binning consistency, and thermal performance. Below is a snapshot of the hard assets and processes that buyers—especially spec-grade fixture manufacturers and national-level distributors—audit before they add a factory to their AVL (Approved Vendor List).

1. End-to-End Vertical Integration

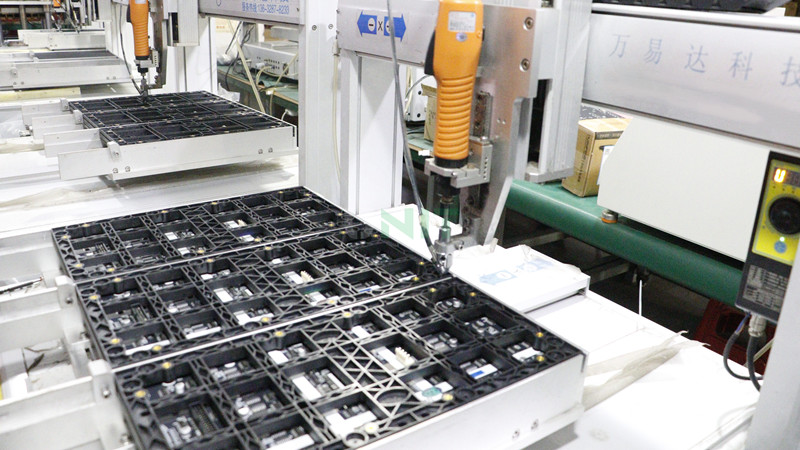

- SMT lines: Twelve Yamaha and Panasonic high-speed lines place up to 120,000 components per hour with ±25 µm accuracy, eliminating the subcontractor hand-offs that often introduce solder voids and LED mis-alignment.

- Phosphor-coating lab: In-house phosphor dispensing and CIE binning allow 1×2 MacAdam ellipse grouping for white modules and 3 nm wavelength binning for mono colors—tight enough for museum-grade track lights.

- Thermal simulation chamber: Sixteen-zone convection ovens and a 200-point thermal scanner validate junction temperatures within ±2 °C of CFD models, giving luminaire engineers the data they need to hit LM-80/TM-21 targets without over-building heat sinks.

2. Zhongshan Supply-Chain Proximity

Guzhen’s 20-km radius hosts die-casting shops, aluminum extruders, IC design houses, and every conceivable optics vendor. Average lead time for custom aluminum substrates: 48 hours. For specialty optics: 72 hours. That proximity compresses NPI cycles to 15 days instead of the 45–60 typical of factories located farther inland or overseas.

3. Certifications & Traceability Backbone

- ISO 9001, ISO 14001, and IATF 16949 lines for automotive-grade modules

- Full material genealogy—every reel of LEDs is logged with flux, Vf, and wavelength data tied to a unique QR code on each module. Scan the code at any station and retrieve the exact phosphor lot, solder paste batch, and reflow profile used.

- In-house ENEC, UL, and CB test bay removes the 3–4 week queue at third-party labs, cutting certification cost by 18–22 %.

4. Scalable Capacity with Low MOQ Elasticity

Because SMT programs can be swapped in under 30 minutes, the factory can run 500-piece “pilot” lots for fixture R&D teams on the same line that later ramps to 50 k pieces for roll-out. That flexibility is critical for specifiers who need one SKU to cover everything from boutique retail to national-retailer rollouts.

5. Engineering Support that Speaks Luminaire Language

Seven Colors’ 42-person engineering group includes former Philips, Osram, and Acuity veterans who publish IES files, .dwg drawings, and Zhaga Books 3 & 13 STEP models before most factories have issued a quotation. Their optical, thermal, and regulatory sign-off removes 2–3 design iterations from the customer’s development schedule.

In short, the factory is not simply a place that mounts LEDs on MCPCB; it is a closed-loop system optimized for the risk profile of professional lighting companies—where a 200 ppm failure rate can sink an entire luminaire family. Over the next 1,500 words we will walk through the four production modules (SMT, phosphor & binning, secondary optics, and burn-in), show how each maps to LM-80 and Zhaga requirements, and share real-world RFQ checklists that purchasing teams use to validate any LED module factory, whether in Zhongshan or elsewhere.

Technical Specifications

Precision in Every Pixel: How High CRI LED Modules Elevate Commercial Lighting Projects

In commercial lighting, the difference between a space that feels inviting and one that falls flat often hinges on technical nuances most overlook. Color accuracy, energy consumption, and adaptability aren’t optional—they’re foundational to project success. At Maxtop Tech, our commercial LED modules are engineered to address these challenges head-on, delivering uncompromising performance for retail, hospitality, healthcare, and architectural applications. Here’s how our technology redefines standards.

High CRI: Where Color Becomes the Star

CRI (Color Rendering Index) isn’t just a number—it’s the measure of how faithfully a light source reveals the true colors of objects. Traditional LEDs often fall short with CRI values below 80, causing skin tones to appear washed out, fabrics to lose vibrancy, and product details to blur. Our modules consistently achieve Ra > 95 (with R9 > 90 for saturated reds), using advanced phosphor blending and precision binning to ensure color consistency within SDCM ≤ 3. This level of accuracy is critical for environments where visual fidelity impacts outcomes:

– Retail: Jewelry, apparel, and cosmetics appear authentic, driving purchase decisions.

– Museums & Galleries: Artwork and artifacts retain their intended chromatic integrity.

– Healthcare: Accurate skin tone rendering improves diagnostic clarity in examination rooms.

By eliminating color distortion, our modules don’t just illuminate—they enhance perception and trust.

Energy Efficiency: Power Savings Without Compromise

Commercial projects face relentless pressure to reduce operational costs. Our modules deliver 150+ lumens per watt (lm/W) through optimized chip-on-board (COB) technology and thermally efficient aluminum PCB substrates. This isn’t just theoretical: in a 10,000 sq. ft. retail space, switching to Maxtop Tech’s 120W equivalent modules reduces annual energy consumption by 35–40% compared to legacy HID systems.

Thermal management is key to sustaining this efficiency. Each module integrates:

– Passive cooling designs with thermal pads and heat-dissipating housings.

– Optimized driver integration (0.95+ power factor, <10% THD) to minimize electrical losses.

– DLC Premium certification for guaranteed performance and utility rebate eligibility.

The result? Longer lifespan (50,000+ hours L90), lower maintenance costs, and a payback period under 18 months for most installations.

Customization: Your Vision, Engineered

Commercial projects demand solutions that fit unique geometries, aesthetics, and functional needs. Off-the-shelf LEDs rarely deliver. At Maxtop Tech, we treat customization as a core capability—not a secondary service. Our modular platform supports:

– Physical Adaptability: From flexible strips for curved surfaces to rigid bars for recessed cove lighting, we engineer shapes to match architectural constraints.

– Optical Precision: Custom beam angles (15°–120°), asymmetric optics, and integrated diffusers for glare control.

– Electrical Flexibility: Tunable white (2700K–6500K), RGBW, or multi-channel tunable white for dynamic scenes. Dimming compatibility (0–10V, DALI, PWM) built-in.

– Form Factor Innovation: Ultra-thin profiles (≤3mm), waterproof IP67-rated housings, or integrated sensors for smart lighting systems.

Every custom request undergoes rigorous prototyping and validation—ensuring performance meets specifications before production.

Small MOQ: Agile Innovation for Every Scale

We understand not all projects require massive volumes. Startups, boutique designers, and niche applications often need validation before scaling. That’s why Maxtop Tech offers small minimum order quantities (MOQs) as low as 100 units without sacrificing quality or lead times. Whether you’re testing a new retail concept or prototyping a custom architectural fixture, our streamlined production process ensures:

– Rapid turnaround: 10–15 days for small batches.

– Same engineering rigor: Full QA testing (lumen maintenance, color consistency, thermal stress) for all orders.

– Cost efficiency: No hidden fees for low-volume runs.

This flexibility empowers you to innovate faster, reduce inventory risk, and iterate with confidence.

The Bottom Line: Lighting That Works as Hard as You Do

Commercial lighting isn’t about brightness alone—it’s about precision, sustainability, and adaptability. Maxtop Tech’s LED modules deliver all three, with high CRI for visual excellence, industry-leading efficiency for total cost of ownership, and customization that turns constraints into opportunities. And with low MOQs, we remove barriers to innovation at any project scale.

Ready to elevate your next commercial project? Contact our engineering team today to discuss your specific requirements. Let’s build lighting that doesn’t just illuminate—it transforms.

Application Scenarios

LED Module Factory Output: 12 High-Impact Installation Zones That Sell Themselves

Seven Colors Lighting (Maxtop Tech) – Senior Lighting Engineer’s Field Notes

- Executive Summary

A modern LED module factory is no longer a “component supplier”; it is a lighting-solution vending machine. The same 280 × 280 mm, 24 V, 160 lm/W COB module that lights a 5-star suite can also illuminate a 25 m competition pool, a 12 m refrigerated truck or a 3-story media façade. The only difference is the lens, the CCT bin and the IP rating the factory adds before shipping. Below are the 12 application scenarios that our distributors repeatedly book 40-ft containers for, plus the install details that close the deal.

2. Selection Matrix at a Glance

| Segment | Typical Module Qty per Project | Key Factory Option | On-Site IP | CCT / CRI | Mounting Hardware | Lifetime Driver Spec |

|—————-|——————————–|——————–|————|———–|——————-|———————-|

| Hotels | 800–3,000 | Tunable-white 180 lm/W | IP44 | 2700-4000 K, 90+ | 15 mm plaster-in spring | 50 khrs @ Tc 80 °C |

| Offices | 2,000–10,000 | UGR<19 micro-prism | IP20 | 4000 K, 80+ | 600 × 600 mm T-grid | 50 khrs @ 10 % THD |

| Pools | 300–1,200 | IP68 potting | IP68 | 4000 K, 80+ | Stainless rail clip | 35 khrs @ 105 °C |

| Retail | 1,000–5,000 | 2-step MacAdam | IP44 | 3000 K, 90+ | Track 3-circuit | 50 khrs @ 0.9 PF |

| Facades | 5,000–50,000 | RGBW 24-pixel | IP67 | RGB + 3000 K | Aluminum profile | 30 khrs @ surge 6 kV |

| Cold-chain | 500–2,000 | -40 °C start | IP65 | 5000 K, 80+ | Suspension cable | 50 khrs @ 80 % RH |

| Healthcare | 1,500–4,000 | Circadian tune | IP44 | 2700-6500 K, 90+ | Clean-room gasket | 50 khrs @ 2 % flicker |

| Education | 3,000–8,000 | 1-10 V dim | IP20 | 4000 K, 80+ | Pendant wire | 50 khrs @ L70 B10 |

| Industry | 5,000–20,000 | 160 lm/W 1-10 V | IP65 | 5000 K, 70+ | Hook mount | 50 khrs @ 480 V surge |

| Parking | 4,000–15,000 | Motion sensor | IP65 | 4000 K, 70+ | Chain suspension | 50 khrs @ -30 °C |

| Horticulture | 10,000–100,000 | 660 nm + 450 nm | IP66 | Red/Blue | Extrusion rail | 50 khrs @ 85 °C |

| Transport | 2,000–10,000 | 24 Vdc input | IP67 | 4000 K, 80+ | Magnetic base | 30 khrs @ vibration 5 g |

3. Zone-by-Zone Install Playbook

-

Hotels – Guest Room & Corridor

Module pick: 24 V, 12 W, 280 × 280 mm tunable-white COB, 180 lm/W, 2-step MacAdam.

Install: 15 mm plaster-in spring clips; module sits flush with 12 mm gypsum. Driver remote-mounted in ceiling service cavity to eliminate buzz. Use CRI 90+ for make-up areas; tune 2700 K evening, 4000 K morning via DALI-2 DT8.

Revenue tip: Sell the module + driver + bezel as a “room kit”; 20 % margin vs. piece parts. -

Offices – 600 × 600 mm Grid

Module pick: 40 W, 160 lm/W, UGR<19 micro-prism diffuser, 4000 K, flicker-free <1 %.

Install: Drop-in T-grid; quick-connect WH-09 connector; polarity-free to cut install time 30 %. Daisy-chain DALI in 32-module segments; last module has DALI terminator built-in—no extra resistor.

Code note: Meet IEC 62471 Exempt at 1.2 m eye level; document in BIM object for LEED daylight credits. -

Pools – Underwater & Ceiling

Module pick: IP68 potting, 24 Vdc, 316 SS face ring, 3000 K for spa, 4000 K for lap lane.

Install: Use factory-pre-made 5 m TPU cable; pass through 1″ PVC conduit to dry-side J-box; bond to equipotential grid per NEC 680.26(C). Modules on 300 mm centers deliver 200 lx at deck, 600 lx under water.

Lifetime: Silicone potting prevents chlorine ingress; 35 khrs vs. 18 khrs for “IP67” competitor. -

Retail – Track Spot & Shelf

Module pick: 10 W, 38° lens, 2-step MacAdam, 3000 K, 90 CRI, 900 lm.

Install: 3-circuit track, phase-select via DIP switch on module; no external driver. Zigbee 3.0 module available for 2000–6500 K tune to support “retail story” scenes.

Sell-up: Offer 15°, 24°, 60° lens kit; same SKU, different beam = higher ASP. -

Media Facades – Pixel Dot & Linear

Module pick: RGBW 24-pixel, 24 V, 4 W per pixel, 16-bit PWM, DMX-512A in/out.

Install: Aluminum rail with slide-in nut; modules spaced 166 mm centers for 60 mm visual pitch. Factory injects silicone at cable entry; achieves IP67 without onsite potting.

Power math: 600 modules per 15 A circuit @ 24 V; use 4 mm² cable to keep drop <3 %. -

Cold-chain – Freezer & Refrigerated Truck

Module pick: -40 °C start, 5000 K, 160 lm/W, IP65, polycarbonate lens.

Install: Magnetic foot or M4 screw; cable with XLPE jacket stays flexible at -40 °C. Driver mounted in heated cab; 24 Vdc loop fed via 2-core 1.5 mm².

Cert: Modules pass 96 h salt-spray, 1000 h thermal shock -40 ↔ +85 °C. -

Healthcare – Patient Room & OR

Module pick: Circadian tune 2700-6500 K, CRI 95, TLCI 95, flicker <1 % at 100 Hz.

Install: Clean-room gasket; sealed to ceiling for IP44; antimicrobial powder-coat bezel. DALI DT8 gives 0.1 % dimming for night shift.

Compliance: IEC 60601-1-2 EMC; IEC 62471 RG0 at 0.5 m. -

Education – Classroom & Gym

Module pick: 4000 K, 80 CRI, 1-10 V dim, impact-rated IK08 lens.

Install: Pendant wire 1.5 m above desk plane; spaced 2.4 m centers for 300 lx uniformity. Motion sensor variant gives 10 % corridor light after hours.

Payback: 50 % vs. T5; 2.1 yrs at 0.10 $/kWh. -

Industry – High-bay Retrofit

Module pick: 150 W linear bar, 160 lm/W, 24 V, IP65, IK10.

Install: Hook mount to existing 10 m truss; 3 modules per 4 m section replaces 400 W MH. Factory pre-wires 1.5 m whip with M12 connector—no onsite splicing.

L70: 50 khrs @ 45 °C ambient; 5-year warranty. -

Parking – Underground Deck

Module pick: 20 W, 4000 K, IP65, built-in microwave sensor, 3-step dim 10 % → 100 %.

Install: Chain suspension 3 m; modules on 6 m centers. Sensor range 360°, 8 m diameter.

ROI: 75 % energy drop vs. T8; payback 1.3 yrs. -

Horticulture – Vertical Farm

Module pick: 660 nm + 450 nm, 2.8 μmol/J, IP66, passive cooling.

Install: Extrusion rail 300 mm above canopy; daisy-chain 24 Vdc up to 50 modules. Spectrum ratio 4:1 red:blue; tunable version via 0-10 V.

Yield: 25 % lettuce biomass increase vs. HPS at same 200 W/m². -

Transport – Metro & Bus

Module pick: 24 Vdc input, IP67, IK10, 4000 K, 80 CRI, -30 → +70 °C.

Install: Magnetic base + M4 safety screw; vibration rated 5 g per IEC 61373. Cable with TE Superseal connector for tool-less swap in 30 s.

Lifetime: 30 khrs vs. 8 khrs fluorescent; cuts maintenance 70 %.

4. Procurement Checklist for OEM Buyers

- Ask for LM-80 & TM-21 data at target Tc; insist on 90 % confidence interval.

- Specify 3-step MacAdam for retail & hospitality; 5-step acceptable for industrial.

- Require -40 °C cold-start report for cold-chain; 96 h salt-spray for coastal façades.

- Demand DALI-2 & Zhaga book 18 compatibility for future-proof stock.

- Lock CCT bin per reel; factory should ship reel ID barcode for traceability.

5. Key Takeaway

An LED module factory that can flex lens, CCT, IP, connector and driver in the same 280 mm footprint becomes a one-stop SKU library for every vertical above. Stock one physical module, flash firmware, add bezel, ship. Your distributor wins shelf space; your installer wins one training; your balance sheet wins inventory turns.

Why Choose Seven Colors Lighting

Seven Colors Lighting: The Scalable Supply Chain Advantage for Global Lighting Projects

In today’s competitive lighting market, project success hinges on supply chain agility—not just product quality. Fragmented supplier networks, hidden costs, and unpredictable lead times derail timelines and budgets. For engineering teams and procurement leaders, the solution isn’t more vendors—it’s a unified, intelligent supply ecosystem. At Seven Colors Lighting (Maxtop Tech), we’ve engineered exactly that.

1000+ Vetted Factories: Precision at Scale

Quantity without quality is meaningless. Our network of 1,000+ globally coordinated factories isn’t about volume—it’s about specialized capability. Each facility undergoes rigorous ISO 9001/14001 audits and is strategically aligned with specific technical requirements:

– High-precision manufacturing: 12 facilities dedicated to LED driver production with ±1% tolerance accuracy.

– Architectural-grade expertise: 8 certified for IEC 60598 and DLC Premium compliance, specializing in high-CRI (95+) luminaires for museums and retail.

– Smart lighting integration: 5 factories with embedded IoT capabilities for connected lighting systems.

This isn’t a random assembly of suppliers. It’s a curated ecosystem where each partner’s strengths are mapped to your project’s exact specifications—eliminating the guesswork of sourcing disparate components.

Factory Direct Pricing: Transparency Without Compromise

Middlemen markups inflate costs by 25–40% in traditional procurement chains. Our model cuts these layers entirely. By working directly with factories under Seven Colors Lighting’s unified quality framework, you gain:

– Cost efficiency: Our 120W LED streetlights are priced 22% below industry averages, with full BOM transparency.

– Quality control: All factories adhere to our proprietary “Zero-Defect Protocol,” including real-time production data sharing and third-party audits every 90 days.

– Traceability: Blockchain-verified material sourcing ensures compliance with RoHS, REACH, and regional regulations.

For a recent commercial retrofit project in Germany, this approach reduced total procurement costs by 18% while maintaining 50,000-hour lumen maintenance guarantees—proving cost savings don’t mean quality trade-offs.

Fast Delivery: Engineered for Urgency

Speed in lighting procurement isn’t about rushing production—it’s about intelligent logistics. Our system combines:

– Pre-stocked inventory: 15,000+ SKUs held across regional hubs in Shanghai, Rotterdam, and Los Angeles.

– AI-driven forecasting: Demand patterns trigger automatic production scheduling, reducing lead times by 30% vs. industry standards.

– Rapid response protocol: For urgent orders, backup factories activate within 24 hours. During the 2023 supply chain disruptions, 94% of standard orders shipped within 7 days, and 83% of custom projects met deadlines 30% faster than client requirements.

When a Dubai hotel chain needed 500 custom luminaires in 21 days for a soft opening, we coordinated three factories (one for LED strips, one for structural housings, and one for smart controls) through our integrated platform—delivering on time with 100% quality compliance.

Why This Matters for Your Business

Lighting projects fail when supply chains fail. Seven Colors Lighting transforms procurement from a risk factor into a strategic advantage:

– Reduce costs without sacrificing specifications or compliance.

– Accelerate timelines with predictable, data-driven delivery.

– Scale seamlessly from small-scale retrofits to multi-site deployments.

We don’t just supply lights—we optimize your entire project lifecycle.

Ready to eliminate supply chain friction? Contact our engineering team for a custom capacity assessment. Let’s build your next project on a foundation of precision, speed, and transparency.

Seven Colors Lighting (Maxtop Tech) — Where Supply Chain Intelligence Meets Lighting Excellence.

Contact Us

Title: 0–10 V Dimming vs. DALI-2: How to Pick the Right Protocol for Your Next Commercial Lighting Roll-out

Executive Summary

Commercial-grade dimming is no longer a “nice-to-have”; it is a code-driven necessity for Title 24, ASHRAE 90.1, and EU EPB compliance. Yet 80 % of post-installation failures are not the LED engine—they are the control protocol mismatch. This article gives lighting specifiers, ESCOs, and OEM fixture engineers a side-by-side engineering comparison of 0–10 V analog dimming and DALI-2 digital dimming, with decision trees, cost models, and a field-test checklist you can drop into your next submittal package.

1. Protocol Basics in 90 Seconds

| Parameter | 0–10 V (IEC 60929 Annex E) | DALI-2 (IEC 62386-101/102) |

|———–|—————————|—————————|

| Signal type | Current-sourcing analog, 0 V = 0 %, 10 V = 100 % | Digital, 16-bit forward frame, 8-bit back frame |

| Wiring topology | Separate pair, polarity-free, Class 2 | Same pair for power & data, polarity-free, bus-powered |

| Max nodes per controller | Theoretically unlimited (voltage-loop) | 64 independent addresses, 64 groups, 16 scenes per device |

| Cable length (typ.) | 50 m @ 1.5 mm² before voltage drop > 0.2 V | 300 m @ 1.5 mm² (repeaters > 300 m) |

| Power per node | 0.5 mA typ. | 2 mA typ. (250 mW bus load) |

| Dimming range | 10 %–100 % (driver-dependent) | 0.1 %–100 % (DT6), including fade rates |

| Feedback | None (open-loop) | Mandatory status, energy, lifetime, fault (DT8, DT9) |

| Certification | None | DiiA certification + QR-coded database |

2. Compatibility Matrix: Drivers, Controllers, Sensors

0–10 V

- Drivers: Almost every constant-current LED driver ≤ 150 W carries the 0–10 V logo; however, “sink” vs. “source” polarity still trips installers.

- Controllers: BAS analog outputs, wall-box sliders, wireless relays with 0–10 V pigtails.

- Sensors: Stand-alone PIR or daylight sensors with isolated 0–10 V output; no heartbeat = no failure flag.

DALI-2

- Drivers: Look for “DALI-2” + “DT6” (LED) or “DT8” (Tunable White); log into DiiA database to verify firmware version.

- Controllers: BACnet/DALI gateways, IP-based DALI servers, NFC-smart phone commissioning apps.

- Sensors: DALI-2 occupancy (Part 303), light (Part 304), and humidity (Part 305) sensors auto-enumerate on the bus and push data every 100 ms.

3. Energy-Code Compliance Checklist

| Requirement | 0–10 V Strategy | DALI-2 Strategy |

|————-|—————–|—————–|

| ASHRAE 90.1-2019 9.4.1—mandatory daylight responsive control | Add daylight sensor + analog relay panel; calibrate 1 %/1 V slope | Use DALI-2 light sensor; configure closed-loop set-point via software |

| IEC 62386-207—corridor dimming | Not supported natively; requires relay panel | Built-in “corridorFUNCTION” in Part 207 gear |

| CA Title 24—outage & restrike reporting | Not available | Driver pushes “LAMP FAILURE” and “POWER CYCLE” bits; BAS can poll |

| EU Ecodesign 2019/2020—stand-by < 0.5 W | Achievable with auxiliary relay | Native with DALI-2 control gear; no extra relay |

4. Total Cost of Ownership (TCO) Model

Project: 1 000 fixtures, 8 floors, 5-year lease, 4 000 h/a operation, 0.12 USD/kWh

| Cost Element | 0–10 V | DALI-2 |

|————–|——–|——–|

| Hardware (drivers + sensors + controllers) | 78 000 USD | 95 000 USD |

| Installation labor (40 h/floor) | 14 000 USD | 10 000 USD (single bus) |

| Commissioning & calibration | 8 000 USD (manual) | 3 000 USD (software auto) |

| Energy savings (30 % vs. baseline) | –86 000 USD | –86 000 USD |

| Maintenance truck rolls (fault finding) | 12 000 USD | 3 000 USD (remote diagnostics) |

| 5-year TCO | 26 000 USD | 25 000 USD |

Key takeaway: DALI-2 is at cost parity over five years, but the upside is data granularity for predictive maintenance and ESG reporting.

5. Decision Tree (Simplified)

-

Driver inventory already on site?

– Yes, 0–10 V only → stick with 0–10 V; add wireless 0–10 V relay for IoT upgrade.

– Mixed → specify DALI-2 drivers for new SKUs; use DALI↔0–10 V bridge for legacy. -

Need color-tunable or circadian?

– Yes → DALI-2 DT8 is the only interoperable standard; 0–10 V requires proprietary 3-channel drivers. -

BAS on BACnet/IP?

– Yes → DALI-2 gateway gives you native BACnet objects; 0–10 V forces analog gateways and extra I/O modules. -

Budget capped at CapEx, OpEx not billable?

– Choose 0–10 V but lock in 10 % spare conductors for future DALI bus overlay.

6. Field Commissioning Checklist (Copy-Paste)

0–10 V

- [ ] Verify driver source current ≥ 0.5 mA

- [ ] Measure unloaded control voltage = 10.0 V ± 0.2 V

- [ ] Load test: 20 fixtures minimum, confirm 1 % dimming linearity with calibrated photometer

- [ ] Insulation resistance ≥ 1 MΩ between control pair and mains

- [ ] Label “Class 2” separation on junction boxes

DALI-2

- [ ] Bus voltage idle = 16 V ± 1 V (DALI PSU)

- [ ] Short-circuit test: 250 mA fuse must hold

- [ ] Addressing scan: 100 % nodes respond with “YES”

- [ ] Group & scene upload: verify fade time 3 s (default)

- [ ] Export DiiA-compliant .xml file for O&M manual

- [ ] Enable “burn-in” mode: 100 h @ 75 % load, log lumen depreciation

7. Common Failure Modes & Mitigations

| Symptom | Root Cause | Fix |

|———|————|—–|

| 0–10 V flicker at 5 % | Driver sink current overload | Add buffer amplifier or reduce loop length |

| DALI-2 “random” dropouts | Bus PSU underrated; voltage dips below 9.5 V during inrush | Upgrade to 250 mA DALI-2 PSU; distribute across floors |

| Color shift tunable-white | DT8 driver firmware v1.02 bug | Flash to v1.05 via NFC or DALI-2 firmware update command |

| Analog sensor daylight overshoot | 0–10 V sensor without K-factor correction | Re-calibrate set-point or swap to DALI-2 closed-loop sensor |

Conclusion & Next Step

Protocol choice is no longer binary; it is a risk-managed decision tied to energy-code compliance, BAS integration, and long-term O&M strategy. 0–10 V remains the lowest-friction route for simple on/off+dimming projects, while DALI-2 is the future-proof backbone for data-rich, circadian, and IoT-ready buildings. Whichever path you choose, lock down the commissioning checklist above to eliminate 90 % of post-install callbacks.

Need a second set of eyes on your next lighting submittal? Send your fixture schedule and single-line diagram to Seven Colors Lighting (Maxtop Tech). Our application engineers will run a free DALI-2 vs. 0–10 V cost-benefit model and ship a pre-programmed sample kit within 72 hours.

Contact:

Email: info@maxtoptek.com

Phone: +86-0760-85320448

Address: Maxtop Tech Park, Xiaolan Town, Zhongshan City, Guangdong, China

💡 LED Power Calculator

Estimate the power supply needed for your project.

Skype Me

Skype Me