Written by Xu Dong, Translated by Win Lu, Reference to https://zhuanlan.zhihu.com/p/28298556

Spectrum is the reasearching basic of Light. Spectrum analysis is necessary to the application quality of light. So led grow light spectrum is specially important. The capacity of designing led grow light spectrum of the manufacturers decide their competition position at the market.

The spectrum of LED plant lights needs to be specially designed according to the planting process and cannot be imitated.

Plant factory is a cross-border product. We divide plant factory technology into planting equipment technology and planting process technology. Plant light spectrum technology is an important connection point between planting equipment and planting process. It should be clear that the planting process determines the spectral design. The design and manufacture of the lamp is to ensure that the light quality required by the planting process can reach the best efficiency. These characteristics of the plant lamp determine the complexity and diversity of the plant spectrum design.

一、 Non-visual applications of the spectrum

Spectral applications are divided into visual applications and non-visual applications. Lighting belongs to visual applications, and plant lighting belongs to non-visual applications. Visual applications and non-visual applications are different in terms of the physical dimensions of the spectrum itself. However, we found many plant lights are still marked as lighting units. Labeling parameters, this parameter labeling that will cause confusion in the application may be derived from the term “plant lighting”.

The essence of the spectroscopic study of plant photosynthesis is the analysis of the distribution form and quantity (light quality) of the optical radiation power or light quantum within the defined range of wavelength. This analysis is achieved through spectral data and spectrograms.

- Sunlight spectrum

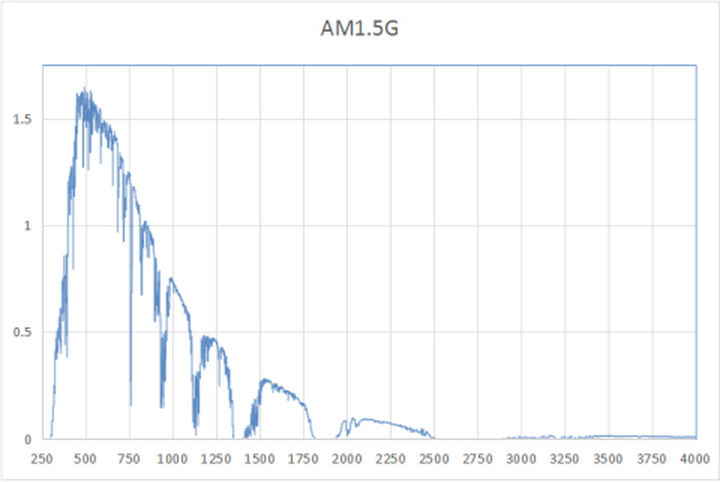

Plant cultivation needs to study the solar spectrum. The solar spectrum tested on the ground belongs to the absorption spectrum. The standard solar spectrum is shown in Figure AM1.5G (G173-03). Due to the geographical location and the season, the amount of spectral radiation measured on the ground will vary. There are differences, but the spectra are the same The photosynthesis of plants, the usual theory is to study the wavelength range of 400nm-700nm. The AM1.5G (the figure below) which limits the wavelength to this range shows that the spectral shape is close to a rectangle.

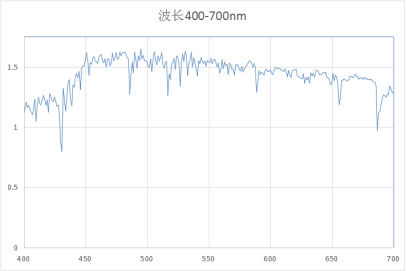

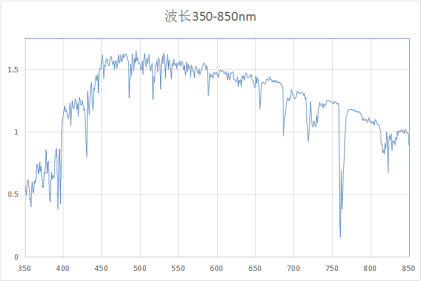

The photosynthesis of plants, the usual theory is to study the wavelength range of 400nm-700nm. The AM1.5G (the figure below) which limits the wavelength to this range shows that the spectral shape is close to a rectangle. In order to provide a reference for the spectral design of artificial light sources, we provide AM1.5G diagrams in the wavelength range of 350-850nm for reference

In order to provide a reference for the spectral design of artificial light sources, we provide AM1.5G diagrams in the wavelength range of 350-850nm for reference  The sunlight spectrum is an important reference for the grow lamp spectrum design, but it is not the necessarities. Trying to imitate the sunlight spectrum to the plant lamp is a futile and inefficient approach.

The sunlight spectrum is an important reference for the grow lamp spectrum design, but it is not the necessarities. Trying to imitate the sunlight spectrum to the plant lamp is a futile and inefficient approach.

The red, green, and blue radiation ratio of AM1.5G in the wavelength range of 400-700nm is:

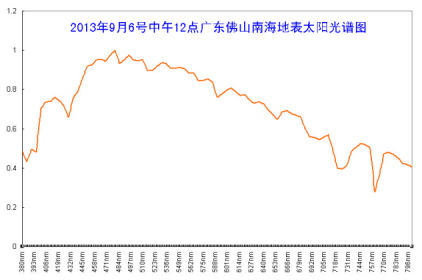

Red light accounted for 32.62%, green light accounted for 35.38%, blue light accounted for 32.69% Analyzing the sunlight in a certain planting area is very important for planting in this area. It should be measured locally with professional instruments so that it can be accurately analyzed. The figure below is the relative spectrum of Nanhai, Foshan in September 2013.

The red, green, and blue radiation ratios of this spectrum in the 400-700nm wavelength range are:

Red light accounted for 28.7%, green light accounted for 36.58%, and blue light accounted for 35.43%. We can see that the red, green, and blue components of the spectrum are different due to different geographic locations, which has a great impact on the design of solar-type and hybrid plant factories. Accurate analysis of the local sunlight spectrum can provide a scientific reference for photosynthesis for the planting process of solar-type and hybrid plant factories, and can correctly provide the basis for the selection of fill light. For solar-type plant factories, accurate spectrum Analysis is more conducive to the way SPA. It should be noted that the spectroscopic analysis dimensions of the solar spectrum and the artificial light source are different. The solar light spectrum is suitable for the description of the radiation dimension, and the artificial light source is suitable for the description of the light quantum dimension. There will be a follow-up article on this issue.

2.The spectrum and limit parameters of the LED light source The spectrum of LED grow lights is discussed as the focus, because the spectrum of the LED light source can be customized according to the requirements of the planting process. At the same time, the spectrum of the LED light source can be controlled by dimming technology. The LED light source is the only one that can be realized at present. The variable-spectrum plant light source and the variable-spectrum technology of plant lights are mainly aimed at light form control, which has little effect on energy saving. Traditional grow lights can also save energy by adjusting the photoperiod, and the application cost of variable spectrum will increase a lot.

• The highest PPF can be calculated according to the spectral statues of the LED

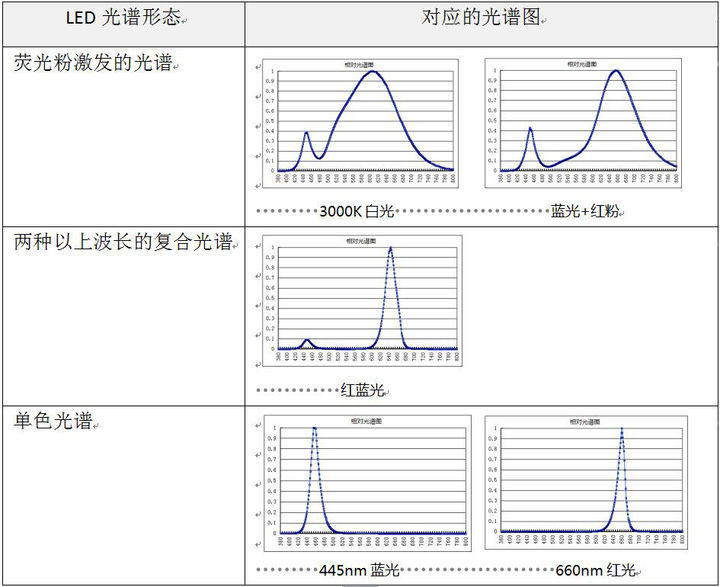

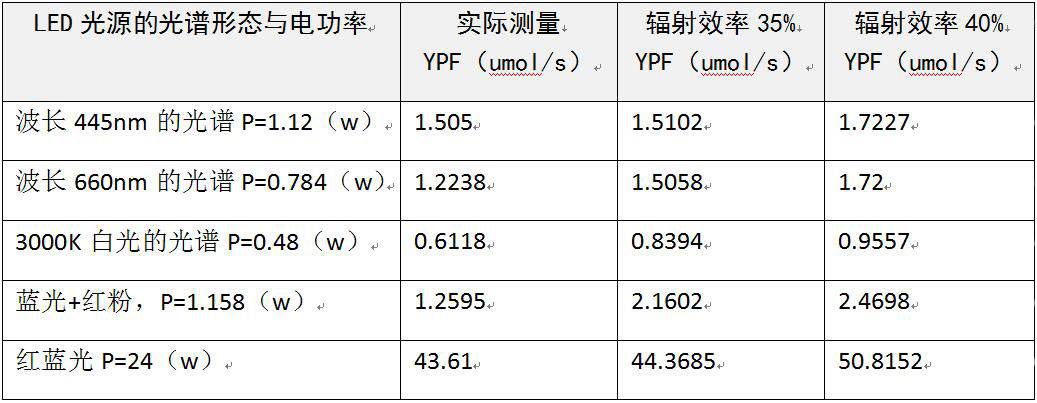

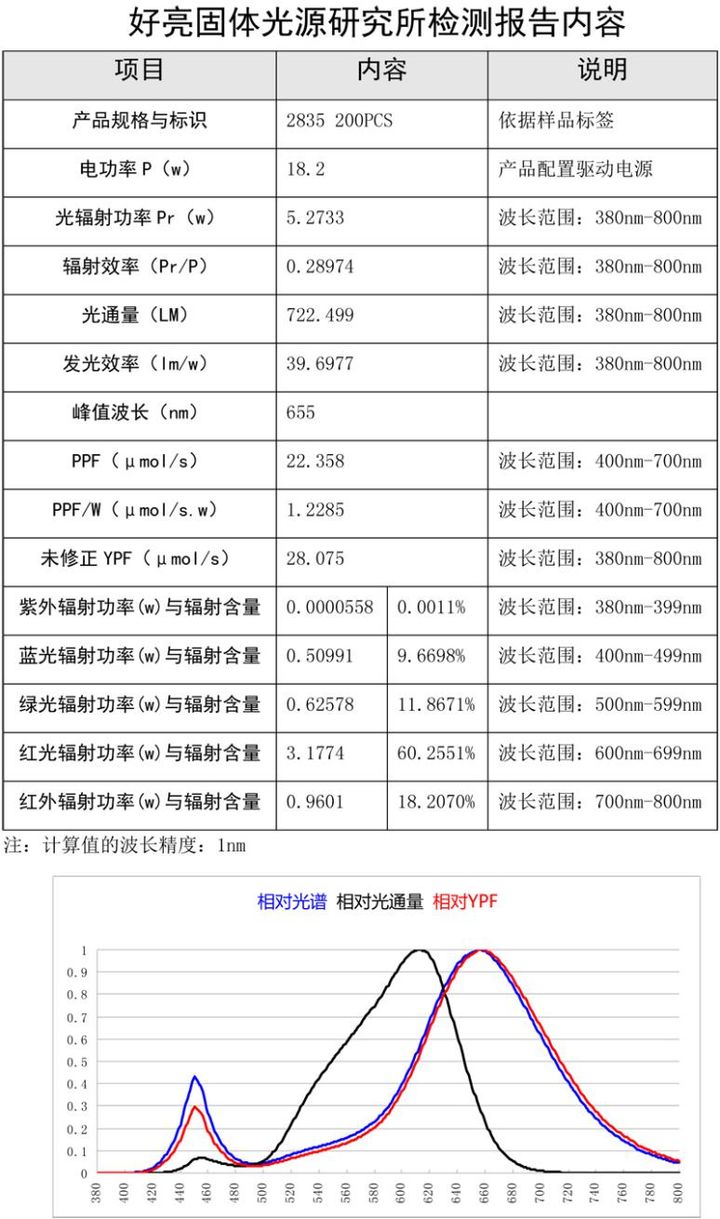

The spectral statues of the LED light source is shown in the following table:

After the spectral form of the plant light is determined, the highest YPF or PPF corresponding to this spectral form can be calculated. This is very important for evaluating the application of LED plant lights, and it is also the main method for comparing the performance of LED plant lights with other types of plant lights. You can refer to the following table we made:

The highest YPF of the current LED packaging technology in bulk supply is less than 40%.

Light source radiation efficiency(YPF) = (radiation power/electric power)×100%

• The spectral design of the LED plant light reflects the manufacturer’s quality capabilities

The spectral design of the LED grow light which is the equipment support capability required by the planting process, is related to the market competitiveness of the plant light manufacturer, and is the main feature of measuring the manufacturer’s technology and process. The spectral design of the plant light reflects LED chip choice and packaging technology of the manufactures, spectral analysis and calculation capabilities of plant lamps, light distribution design of lamps, light quantum field uniformity control, drive technology, heat dissipation technology, product reliability control, installation structure design and other comprehensive manufacturing levels. All of these mark the manufacturer technical strength of the products in the market. The application of the above-mentioned aspects to evaluate plant light products can reduce investment risks and procurement risks.

二、the main points of the spectrum design of LED plant lights

The spectral design of the LED grow light is the technical expression ability required by the planting process and reflects the manufacturing qualification of the manufacturer.

1.The manufacturing process of plant lights affects the PPFD value

The planting process often needs to refer to the daily radiation based on a certain light quality or the PPFD value of the planting surface (some planting processes require YPFD) and photoperiod. The daily radiation determines the PPFD value and photoperiod. Designers can Calculate the PPF value (or YPF value) of the LED light source based on the PPFD value, and then perform the spectral design;however, we need to notice that under the same light source PPF value, different light distribution design, heat dissipation design, and drive design can lead to significant differences in PPFD value.The manufacturing process also has a greater impact on the power utilization efficiency of grow lights. This influence can be measured by the PPF value and PPFD value per watt of electrical power. The higher the value, the better.

For LED light source: PPF/w, for planting area: PPFD/w, comparing these two indicators of plant lights with the same spectral form, we can evaluate the manufacturer’s process level by it.

2. There is no best LED grow light spectrum but only most suitable

The spectrum can be diverse because it can be designed. The spectrum of each plant lamp is advertised as the best by the designer. We emphasize here thatThere is no best spectrum, but only the most suitable for planting process.Trying to make the LED spectrum universal is not a good design idea. The highly compatible spectrum design is at the expense of planting efficiency and waste of electrical energy.

3.Pay attention to the uniformity of the radiation field on the area

For the combination grow lighting spectrum of a variety of single-wavelength lamp beads,the uniformity of the radiation area after the mixing of the multiple radiation needs to taken into consideration, mainly the arrangement of the lamp beads, the light distribution design, and the installation height of the lamps;The uniformity of the radiation field affects the photosynthetic efficiency. For stereoscopic planting,please try to use Lambert light distribution. For greenhouse lighting making-up plant lights with lenses, we need to pay more attention to the uniformity of the radiation field.What needs to be clear is that the result of improving the uniformity of the radiation surface by increasing the installation height is to reduce the PPFD value at the rate of the second power of the distance.

4. Focus on the efficiency of plant lights

The lamp efficiency of the plant lamp is the ratio of the PPF value of the lamp to the PPF value of the light source. And this valus is less than 1. Related to the light distribution design of the secondary optics, the efficiency of the LED plant light is usually between 0.9-0.5. Lamp efficiency affects the energy consumption index and planting efficiency. The efficiency of the plant light fixture with lens design will not exceed 0.8.

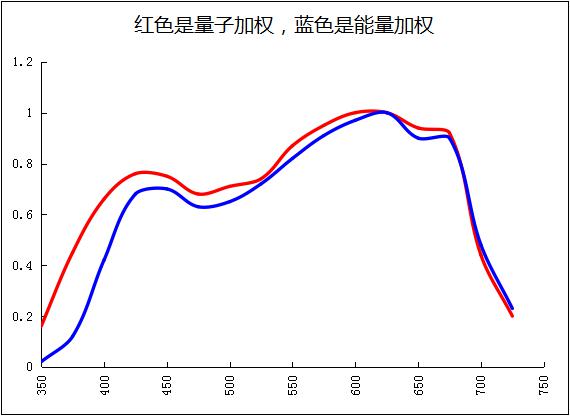

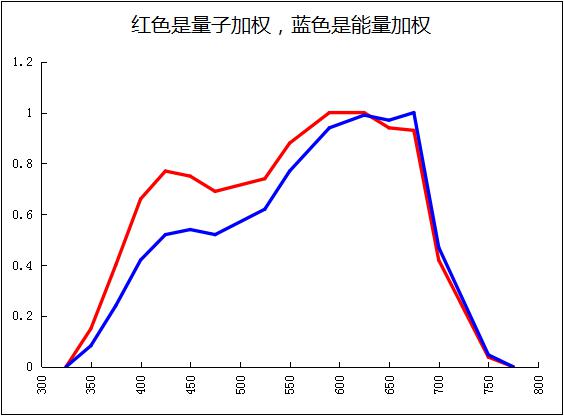

5.About the weighting of the grow light spectrum

Grow light spectral weighting (RQE) can solve the contradiction between plant absorption efficiency and energy consumption better.The same as the lighting visual effect function is the plant absorption efficiency function (also called the action curve). The spectral weighting of some plant lights is based on the Mokley curve (Figure 1) or the revised one based on Mokley curve (Figure 2) by adding plant varieties on Japanese trend. We need to note that the LED light source was not used in Mokley’s research. Meanwhile, Mokley’s research is based on a summary of low-radiation and integrated indoor and outdoor planting data of a few varieties. Although Japan’s revised curve has added plant varieties, the above-mentioned problems still exist. Compared with the German industrial standard, they focus on blue light. So we believe that these weights are not entirely suitable for LED light sources. The spectral V weighting we do for the LED light source (omitted) is just an idea. How to weight the spectrum is still the research direction for every countries.

6. Regarding the spectrum ratio

So far, we still use the lamp bead ratio of various spectra to describe many led grow lights when they talk about the spectrum ratio.Since the lamp bead ratio cannot reflect the amount of radiation, this problem requires knowing about the LED chip supply specifications. LED chips are graded and supplied according to the radiation power of the same chip size. According to the lamp bead ratio, there may be 30% different on the provided led spectrum. This is to illustrate why the planting effects differ in different batches of the same product.The correct spectral ratio is the radiant power ratio of the RGB wavelength according to the PAR wavelength range. Thus the products provided in this way will have data basis. The following is our data analysis on a certain product for your reference:

7.Adding UV and IR wavelength spectrum is necessary

Adding UV and IR wavelength spectrum, the planting process is mainly to control the light form of plants. For LED plant lights with UV and IR sections, it is not appropriate to use micromolar expressions, but to use radiation parameters to describe. In the meantime Provide PPF and YPF values , otherwise, it will not be able to correctly express the UV and IR radiation requirements of the planting process.

三、Clarify the planting process determines the plant light spectrum design

The design basis of plant lights is the planting technology. For example, if the daily radiation dose of lettuce is too large, it will lead to physiologically impaired calcium deficiency. And this maybe leads to light suppression. So reasonable total amount of daylight setting is very important.

Planting techniques include: the daily radiation amount of plant photosynthesis and the total amount of radiation in the planting cycle, plant varieties and provenance, whether LDP or SDP, planting methods and substrates, planting environment and control, etc.

The led grow light spectral shape and daily radiation amount closely related to planting are first determined by the planting process of the planted variety.In our design specifications, we adopt the planting technology expert system,in which daily radiation of plant cultivation determines PPFD and light period. PPFD determines PPF; PPF determines the design and technology of plant lights; PPFD determines the installation height and quantity of lamps; and PPFD also determines the amount of ventilation and the supplement of carbon dioxide. All these parameters can be calculated, and the planting cost can be calculated from the total amount of radiation. We can find what the environment is and the method to grow which variety takes priority over the spectral shape and radiation quantity (light quality) in order to design the correct led plant light spectrum. Plant growing technology is an internal factor that closely links agricultural planting with industrial control. Therefore, the grow light spectral design can only be rooted from planting process requirements

- Mixed greenhouse light For greenhouse planting and hybrid plant factories that adopt the combination of sunlight and supplementary light, the accurate method is to make natural light radiation field spectral analysis to determine the amount of supplementary light. For the sites without spectral analysis, we can test the average value of illuminance. Then divide the value by 55 to get the PPFD value of the planting area under sunlight. We can define the suplimentary lighting amount of the led grow lights by this value. This simple method is very useful for project planning and cost budget.Hybrid greenhouse light can reduce or eliminate the use of green light wavelength. Whether it needs green light radiation supplementation or not depends on testing green light radiation amount of direct and scattered light from the sun. Regarding the mechanism of green light radiation on plant cultivation, we will make a special introduction later.

- Spectrum in a completely artificial environment Planting in a completely artificial environment, although the red and blue wavelength lighting has a significant effect on the planting of leafy vegetables, the taste of hydroponic vegetables is still the key to improving the quality of vegetables. So we recommend using the spectrum of white light plus red light. Spectral design in a completely artificial environment requires comprehensive consideration of factors such as carbon dioxide concentration, ventilation, ambient temperature, substrate or nutrient solution control, and shelf structure design. In order to increase planting layers, many layered three-dimensional plantingsuppliers try their best to minimize the height of the nutrient tank. This method will reduce the nutrient fliud and affect the spectrum absorption efficiency. The important goal of spectral design in a completely artificial environment is the quality control of planting. Just completing the process of plant growth hjas no market competition power.

四、As for the full spectrum Some LED plant light suppliers often announce their lights as full spectrum, which may be to express their rich spectral components. There is a key concept here, that is, how the “full” of the full spectrum is defined, who defines it, and how wide the wavelength range can be called “full”. Although the spectrum of sunlight is the most complete, when studying photosynthesis of plants under sunlight, the PAR value is only described in the range of 400nm-700nm. Many nominal full-spectrum LED plant lights have UV and IR partial Wavelength, but they still use PPFD to describe their parameters. Since PPFD does not describe the amount of UV and IR radiation, the parameter description of this full-spectrum plant lamp commits low-level errors. We believe that the plant light wavelength range is just the definition of the spectral absorption efficiency function, not the value range of the absorption efficiency function. Only the spectrum absorption efficiency is the indicator to measure the effect of photosynthesis. The wide-wavelength or multi-wavelength spectrum called the full spectrum can not represent the effectiveness and compatibility of plant lights. It is not accurate to describe the plant light in the full spectrum, which will often mislead the grower’s application; The setting of the spectrum wavelength definition range is still related to the planting process. The planting process determines the specturm definition range design. Not the growing bases on the spectrum design. Plant lights and plant factories are cross-border products. Some phenomena are that industrial people are busy studying planting, and agricultural people are busy studying spectrum. Knowledge extension is only for communication and understanding. The professional cooperation and division of labor in the spectrum design are more conducive to the rapid development of the industry.

五、the complexity of plant light spectrum research As far as the LED light source is concerned, even if the PPFD value is same, the spectral state can be different; For the same PPFD, the ppf value of the light source required for the secondary optical design is also different; The same ppf value, the lamp efficiency is different, and the PPFD value is also different;Even if the above conditions are the same, the plant’s provenance is different, the growth environment and the substrate are different, and the planting effect is also different; In addition, the same LED plant light is also affected by environmental factors such as carbon dioxide concentration, ventilation, and temperature control. When the planting efficiency and quality meet the planting process requirements, the plant lights need the manufacturing process at the most to ensure to minimize energy consumption indicators.This is very important. The complexity of spectrum research shows the diversity of current plant lights. Because there is no evaluation standard at present, the led grow lights on the market are flourishing, and hundreds of schools are competing for fame.

六、Cooperating with professional technology is the best way to improve the industry Grow lights involve a wide range of technologies and belong to cross-border products. No matter how rich you are, considering the development cost, it is difficult to integrate multi-disciplinary talents.The more important thing is to solve the problem of after-sales technical support.For cross-border products, mature experience is to take the road of cooperative development; Farmers strive to study planting techniques , this is the key to the success or failure of plant lights and plant factories.Industrial people make equipment that meets the requirements of the planting process, which affects planting costs and economic benefits. Only professional cooperation can promote the rapid development of new-type agricultural planting with a controllable artificial environment; only the right ideas can have opportunities. Plant lamps are different from lighting lamps. The application target of lighting products is the end customer. You can use the concept and foresight to market. The plant light is only a tool for agricultural planting. Whether it has an effect can not be described by advertisement, it needs practical application to test. Whether the application of plant lights can achieve the expected results is not only a problem of the plant lights itself, but also it is related to many other technical factors. It is necessary to provide reasonable technical solutions. The marketing of plant lights belongs to product marketing with technical support as the main means. Successful cases often reflect successful technical services. In the absence of technical standards, it is crucial to provide technical solutions, and companies need to treat it seriously.

Skype Me

Skype Me